ʻO nā loina o ka welding laser

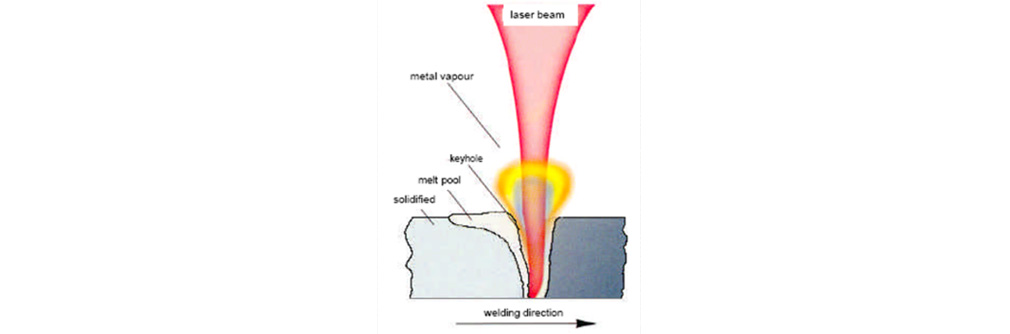

Hoʻopili laserhoʻohana i nā hiʻohiʻona kuhikuhi maikaʻi a me ka mana kiʻekiʻe o kahi kukuna laser e hana.Ma o ka ʻōnaehana optical, ua kālele ʻia ka kukuna laser ma kahi wahi liʻiliʻi loa, e hana ana i kahi kumu wela nui i loko o kahi manawa pōkole loa.Hoʻoheheʻe kēia kaʻina i ka mea ma ka lae hoʻoheheʻe, e hana i kahi wahi weld paʻa a me ka hili.

·Hoʻokaʻawale pinepine ʻia ʻo Laser welding i ka conduction welding a me ka deep penetration welding.

·He 10 ka nui o ka mana laser5~106w/cm2ka hopena i ka welding conduction laser.

·He 10 ka nui o ka mana laser5~106w/cm2ka hopena i ka welding komo hohonu laser.

Nā ʻano o ka welding laser

Hoʻohālikelike ʻia me nā ʻano hana welding ʻē aʻe, loaʻa i ka welding laser nā ʻano aʻe:

·ʻO ka ikehu i hoʻopaʻa ʻia, ka maikaʻi kuʻihao kiʻekiʻe, ka pololei kaʻina hana kiʻekiʻe, a me kahi ratio hohonu-a-ākea nui o ka weld seam.

·Hoʻokomo wela haʻahaʻa, wahi liʻiliʻi i hoʻopili ʻia i ka wela, liʻiliʻi ke koʻikoʻi koena, a me ka deformation haʻahaʻa o ka mea hana.

·ʻO ka hoʻopili ʻole ʻana, ka lawe ʻana i ka fiber optic, ka hiki ke komo, a me ke kiʻekiʻe o ka automation.

·Hoʻolālā hui maʻalahi, mālama i nā mea maka.

·Hiki ke hoʻomalu pono ʻia ka ikehu welding, e hōʻoiaʻiʻo ana i nā hopena kuʻihao paʻa a me kahi hiʻohiʻona maikaʻi.

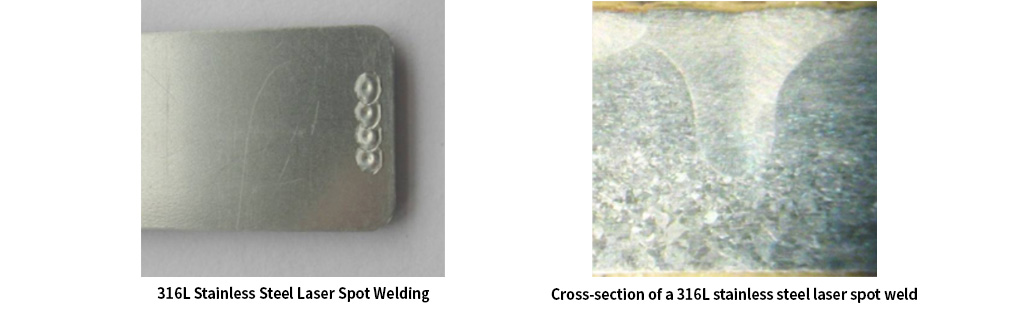

Huina kila a me kona mau huila

·Hiki i ke kila kila ke hoʻokō i nā hopena kuʻihao maikaʻi me ka hoʻohana ʻana i ka nalu square maʻamau.

·I ka hoʻolālā ʻana i nā hale welded, e hoʻāʻo e mālama i nā wahi weld mai nā mea non-metallic e like me ka hiki.

·No ka hoʻokō ʻana i nā koi ikaika a me nā hiʻohiʻona, ʻoi aku ka maikaʻi o ka mālama ʻana i kahi wahi wiliwili kūpono a me ka mānoanoa mea hana.

·I ka wā wili, pono e hōʻoia i ka maʻemaʻe o ka mea hana a me ka maloʻo o ke kaiapuni.

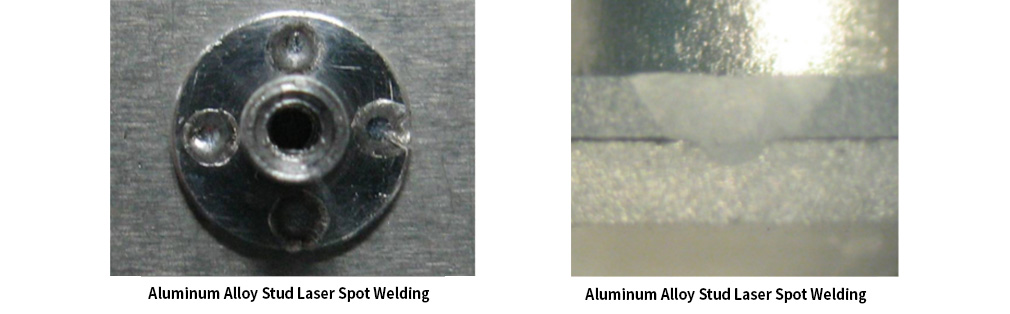

Ka wiliwili ana i ka Aluminum a me kona mau huila

·Loaʻa i nā mea alumini alumini i ka reflectivity kiʻekiʻe;no laila, pono ka mana kiʻekiʻe laser peak i ka wā wili.

·Loaʻa nā māwae i ka wā o ka wiliwili ʻana i ka pulse, e pili ana i ka ikaika wili.

·Hiki ke hoʻokaʻawale ʻia ke ʻano mea, e alakaʻi ana i ka splattering.He mea maikaʻi e koho i nā mea waiwai kiʻekiʻe.

·ʻO ka maʻamau, ʻo ka hoʻohana ʻana i kahi nui nui a me ka laula pulse lōʻihi hiki ke loaʻa nā hopena kuʻi ʻoi aku ka maikaʻi.

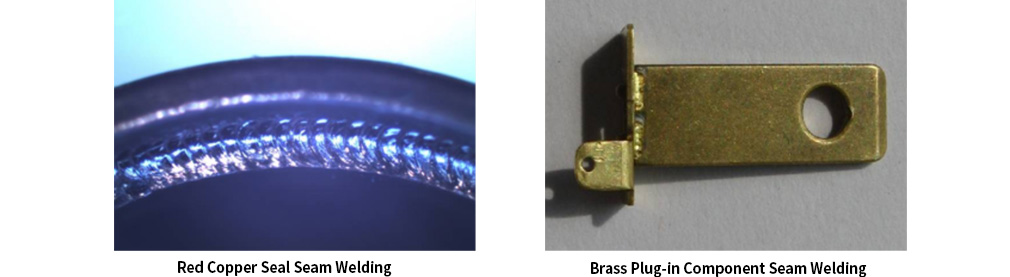

Huina keleawe a me kona mau huila

·ʻOi aku ka kiʻekiʻe o nā mea keleawe i hoʻohālikelike ʻia me nā alumini alumini, e koi ana i ka mana laser kiʻekiʻe no ka wili.Pono ke poʻo laser e hili ʻia ma kekahi kihi.

·No kekahi mau keleawe keleawe, e like me ke keleawe a me ke keleawe, ua hoʻonui ʻia ka paʻakikī wili ma muli o ka mana o nā mea hao.Pono e noʻonoʻo i ke koho ʻana i nā ʻāpana kaʻina hana welding.

Kuʻi Metala ʻokoʻa

·Hiki ke hana ʻia kahi hāʻina paʻa.

·Aia kekahi ʻokoʻa nui i ka electronegativity ma waena o nā metala like ʻole.

·ʻO nā kumu hoʻololi ʻē aʻe.

Hiki i nā metala ʻokoʻa ke hana i nā hui kuʻi kiʻekiʻe e pili ana i nā waiwai kino, nā waiwai kemika, ka haku mele, a me nā ana hana o nā metala e welded.Manaʻo pinepine ʻia kēia mai nā ʻano aʻe:

·Hiki ke hoʻokumu ʻia kahi hopena paʻa ma muli o ka hiki ke hoʻoheheʻe ʻia nā metala like ʻole i loko o ka wai a me nā mokuʻāina paʻa.I ka wā e hiki ai iā lākou ke hoʻoheheʻe i kekahi i kekahi me ka pau ʻole, hiki ke hoʻokumu ʻia kahi hui weld ikaika a paʻa.ʻO ka mea maʻamau, hiki ke hoʻokō ʻia kahi solubility koʻikoʻi, a i ʻole hiki i ka solubility palena ʻole, ke loaʻa ka ʻokoʻa radius atomic ma waena o nā metala ʻelua ma mua o 14% a 15%.

·He mea koʻikoʻi nō hoʻi inā he ʻokoʻa koʻikoʻi o ka electronegativity ma waena o nā metala like ʻole.ʻOi aku ka nui o ka ʻokoʻa, ʻoi aku ka ikaika o ko lākou pili kemika, kahi e alakaʻi ai i ka hoʻokumu ʻana o nā pūhui ma mua o nā hopena paʻa.ʻO ka hopena, ua hoʻemi ʻia ka solubility o ka hopena paʻa i hana ʻia, a ʻoi aku ka haʻahaʻa o ka ikaika o ka hui weld.

·Hoʻohui ʻia, hoʻopili nui ʻia ka welding o nā metala like ʻole e nā waiwai e like me nā melting point, coefficients of thermal expansion, thermal conductivities, specific heats, oxidizability, and reflectivity of the materials.ʻO ka ʻoi aku ka nui o ka ʻokoʻa o kēia mau waiwai kino, ʻoi aku ka paʻakikī o ka weld, a ʻoi aku ka nāwaliwali o ka ikaika o ka hui weld hopena.

·ʻO ka maʻamau, ʻo ka welding laser o nā mea metala like ʻole e like me ke kila me ke keleawe, ka aluminika, a me ka nickel, a me ke keleawe me ka nickel, e hōʻike ana i ka weldability maikaʻi, e alakaʻi ana i ka maikaʻi o ka welding maikaʻi.

Loaʻa i ka welding laser i nā noi nui ma nā ʻāpana like ʻole, me ka ʻaʻole i kaupalena ʻia i kēia mau wahi:

1: Kuʻi Metala ʻokoʻa

Hoʻohana nui ʻia ka welding laser i nā ʻoihana hana e like me ka automotive, aerospace, electronics, a me mechanical engineering.Hoʻohana ʻia ia no ka hoʻopili ʻana i nā ʻāpana a me ka hoʻohui ʻana i nā hale, hoʻonui i ka pono hana a me ka maikaʻi o ka huahana.

2: Nā Lapaʻau Lapaʻau

I ka hana ʻana i nā mea lapaʻau, hoʻohana ʻia ka welding laser no ka hoʻopili ʻana a me ka hui ʻana i nā mea liʻiliʻi, pololei, e hōʻoiaʻiʻo ana i nā huahana kiʻekiʻe ʻoiai e pale ana i ka hopena wela nui i nā mea.

3: Electronics

Ma muli o kāna kikoʻī kiʻekiʻe a me ka hoʻokomo wela haʻahaʻa, ua hoʻohana nui ʻia ka welding laser i ka hana ʻana i nā mea uila, e komo pū me ka wili ʻana o ka papa kaapuni a me nā ʻāpana microelectronic.

4: Aerospace

Hoʻohana ʻia ka welding laser i ka ʻāpana aerospace no ka hana ʻana i nā mokulele a me nā ʻāpana aerospace, e hiki ai i ka hoʻolālā māmā a me nā pilina ikaika.

5: Māhele ʻOihana

I ka ʻoihana ikehu, hoʻohana ʻia ka welding laser no ka hana ʻana i nā panela solar, nā lako mana nuklea, a me nā mea ʻē aʻe e pili ana i ka hana ikehu.

6: Nā mea nani a me ka hana wati

Hāʻawi ʻia i kona hiki ke hoʻololi i nā hale maikaʻi a paʻakikī, hoʻohana pinepine ʻia ka welding laser i ka hana ʻana i nā mea nani a me nā wati no ka hoʻopili ʻana a me ka hoʻoponopono ʻana i nā ʻāpana palupalu.

7: ʻOihana Kaʻa

I ka hana kaʻa, hoʻohana ʻia ka welding laser no ka hoʻopili ʻana i nā ʻāpana automotive, hoʻomaikaʻi i ka pono welding, a hoʻonui i ka maikaʻi o ka huahana.

ʻO ka holoʻokoʻa, ʻo ke kiʻekiʻe kiʻekiʻe, ka wikiwiki, a me ka versatility o ka welding laser e hoʻohana nui ʻia i ka hana ʻana a me nā māla hana.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。

Ka manawa hoʻouna: Jan-17-2024