Laser tu tshuab siv nqaim mem tes dav, siab zog ceev lasers ntawm qhov chaw ntawm cov khoom yuav tsum tau ntxuav.Los ntawm kev sib xyaw ua ke ntawm kev vibration ceev, vaporization, decomposition, thiab ntshav plasma tev, kab mob, xeb stains, los yog coatings nyob rau saum npoo undergo instant evaporation thiab detachment, ua tiav qhov chaw tu.

Laser tu muaj qhov zoo xws li tsis sib cuag, ib puag ncig tus phooj ywg, zoo precision, thiab tsis muaj kev puas tsuaj rau lub substrate, ua rau nws muaj feem xyuam rau ntau yam scenarios.

Laser ntxuav

Ntsuab thiab Siv tau

Kev lag luam log tsheb, kev lag luam tshiab zog, thiab kev tsim kho tshuab kev lag luam, thiab lwm yam, dav siv laser tu.Nyob rau hauv lub era ntawm "dual carbon" lub hom phiaj, laser tu yog tshwm sim raws li ib tug tshiab kev daws teeb meem nyob rau hauv cov tsoos tu lag luam vim nws high efficiency, meej controllability, thiab environmentally friendly yam ntxwv.

Lub tswv yim ntawm Laser Cleaning:

Laser tu yuav tsom rau cov kab teeb laser ntawm cov khoom nto kom sai vaporize los yog tev tawm cov kab mob ntawm qhov chaw, ua tiav cov khoom ntxuav.Piv nrog rau ntau yam kev siv lub cev los yog tshuaj ntxuav tu, laser tu yog tus cwj pwm los ntawm tsis muaj kev sib cuag, tsis muaj consumables, tsis muaj kuab paug, siab precision, thiab tsawg los yog tsis muaj kev puas tsuaj, ua rau nws yog ib tug zoo tagnrho xaiv rau tiam tshiab ntawm industrial tu tshuab.

Lub hauv paus ntsiab lus ntawm Laser Cleaning:

Lub hauv paus ntsiab lus ntawm kev ntxuav laser yog complex thiab tej zaum yuav koom nrog ob qho tib si lub cev thiab tshuaj txheej txheem.Feem ntau, cov txheej txheem ntawm lub cev muaj zog, nrog rau cov tshuaj tiv thaiv ib nrab.Cov txheej txheem tseem ceeb tuaj yeem muab faib ua peb hom: txheej txheem vaporization, txheej txheem poob siab, thiab txheej txheem oscillation.

Txheej txheem Gasification:

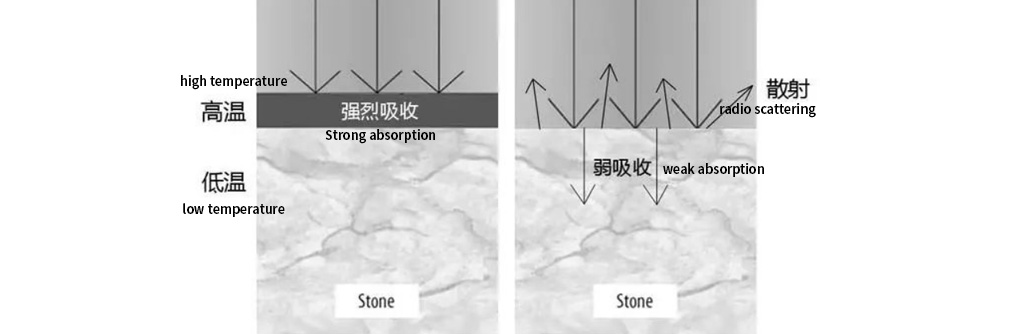

Thaum lub zog hluav taws xob laser irradiation yog siv rau saum npoo ntawm cov khoom, qhov saum npoo absorbs lub zog laser thiab hloov mus rau hauv lub zog sab hauv, ua rau qhov kub thiab txias kom nrawm.Qhov no kub nce mus txog los yog tshaj qhov kub ntawm vaporization ntawm cov khoom, ua rau cov kab mob detach los ntawm cov khoom nto nyob rau hauv daim ntawv ntawm vapor.Kev xaiv vaporization feem ntau tshwm sim thaum tus nqi nqus ntawm cov kab mob mus rau lub laser yog siab dua li ntawm cov substrate.Ib qho piv txwv ntawm daim ntawv thov yog kev ntxuav cov av ntawm cov pob zeb.Raws li pom nyob rau hauv daim duab hauv qab no, cov kab mob ntawm lub pob zeb nto tau nqus cov laser thiab sai sai vaporized.Thaum cov kab mob raug tshem tawm tag nrho, thiab lub laser irradiates lub pob zeb nto, qhov nqus tsis muaj zog, thiab ntau lub zog laser yog tawg los ntawm pob zeb nto.Yog li ntawd, muaj qhov hloov me me ntawm qhov kub ntawm lub pob zeb nto, yog li tiv thaiv nws los ntawm kev puas tsuaj.

Ib qho txheej txheem feem ntau cuam tshuam nrog kev ua tshuaj lom neeg tshwm sim thaum ntxuav cov kab mob organic nrog ultraviolet wavelength lasers, txheej txheem hu ua laser ablation.Ultraviolet lasers muaj luv wavelengths thiab ntau dua photon zog.Piv txwv li, KrF excimer laser nrog lub wavelength ntawm 248 nm muaj lub zog photon ntawm 5 eV, uas yog 40 npaug siab dua li ntawm CO2 laser photons (0.12 eV).Xws li photon siab zog yog txaus los rhuav tshem cov molecular bonds nyob rau hauv cov ntaub ntawv organic, ua rau cov CC, CH, CO, thiab lwm yam., bonds nyob rau hauv cov organic contaminants mus tawg thaum absorbing lub photon zog ntawm lub laser, ua rau pyrolytic gasification thiab tshem tawm los ntawm lub cev. nto.

Cov txheej txheem poob siab hauv Laser ntxuav:

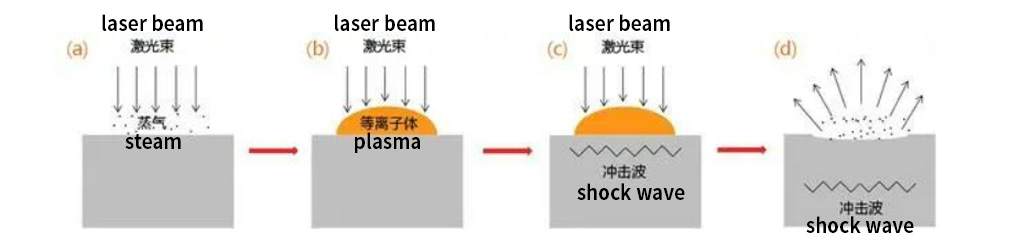

Cov txheej txheem poob siab hauv laser tu muaj ntau qhov kev tshwm sim uas tshwm sim thaum muaj kev cuam tshuam ntawm lub laser thiab cov khoom, uas ua rau muaj kev poob siab tsis zoo cuam tshuam rau cov khoom nto.Raws li kev cuam tshuam ntawm cov kev poob siab no, cov kab mob saum npoo tawg tawg mus rau hauv cov plua plav lossis cov khoom tawg, tshem tawm ntawm qhov chaw.Cov txheej txheem ua rau cov kev poob siab no muaj ntau yam, suav nrog cov ntshav plasma, vapor, thiab thermal expansion thiab contraction phenomena.

Noj plasma shock waves ua piv txwv, peb tuaj yeem nkag siab luv luv li cas cov txheej txheem poob siab hauv laser ntxuav tshem tawm cov kab mob ntawm qhov chaw.Nrog rau daim ntawv thov ntawm ultra-luv mem tes dav (ns) thiab ultra-siab ncov lub zog (107- 1010 W / cm2) lasers, qhov kub ntawm qhov chaw tuaj yeem nce siab rau qhov kub thiab txias txawm tias qhov nqus ntawm lub laser tsis muaj zog.Qhov kub ceev no ua rau vapor saum npoo ntawm cov khoom, raws li qhia hauv daim duab (a).Lub vapor kub tuaj yeem ncav cuag 104 - 105 K, txaus rau ionize lub vapor nws tus kheej lossis cov huab cua ib puag ncig, tsim cov ntshav.Lub plasma blocks lub laser los ntawm ncav cuag cov khoom nto, tejzaum nws halting nto vaporization.Txawm li cas los xij, lub plasma tseem nqus lub zog laser, ntxiv rau nws qhov kub thiab tsim kom muaj lub xeev ntawm qhov kub thiab txias.Qhov no ua rau muaj kev cuam tshuam ib ntus ntawm 1-100 kbar ntawm cov khoom nto thiab nce mus rau sab hauv, raws li qhia hauv cov duab kos (b) thiab (c).Nyob rau hauv qhov cuam tshuam ntawm kev poob siab yoj, cov kab mob ntog tawg mus rau hauv cov plua plav me me, cov khoom me me, lossis cov khoom tawg.Thaum lub laser txav deb ntawm qhov chaw irradiated, lub plasma ploj tam sim ntawd, tsim kom muaj lub zog tsis zoo hauv zos, thiab cov khoom los yog cov khoom sib cais raug tshem tawm ntawm qhov chaw, raws li qhia hauv daim duab (d).

Oscillation txheej txheem hauv Laser ntxuav:

Hauv cov txheej txheem oscillation ntawm laser tu, ob qho tib si cua sov thiab txias ntawm cov khoom tshwm sim sai heev nyob rau hauv lub cuam tshuam ntawm luv-mem tes lasers.Vim qhov sib txawv thermal expansion coefficients ntawm ntau yam ntaub ntawv, cov kab mob ntog thiab cov substrate undergo high-frequency thermal expansion thiab contraction ntawm txawv degrees thaum raug luv-mem tes laser irradiation.Qhov no ua rau muaj cov nyhuv oscillatory uas ua rau cov kab mob tev tawm ntawm cov khoom nto.

Thaum lub sij hawm tev txheej txheem no, cov khoom vaporization yuav tsis tshwm sim, thiab tsis yog plasma tsim nyog.Hloov chaw, cov txheej txheem cia siab rau lub zog shear tsim los ntawm kev sib tshuam ntawm cov kab mob thiab cov substrate nyob rau hauv qhov kev txiav txim oscillatory, uas ua txhaum kev sib raug zoo ntawm lawv.Cov kev tshawb fawb tau pom tias me ntsis nce lub kaum sab xis ntawm laser tshwm sim tuaj yeem txhim kho kev sib cuag ntawm lub laser, cov kab mob sib kis, thiab qhov cuam tshuam ntawm substrate.Txoj hauv kev no txo qis qhov pib rau kev tu lub laser, ua rau cov nyhuv oscillatory ntau tshaj tawm thiab txhim kho kev tu kom zoo.Txawm li cas los xij, lub kaum sab xis ntawm qhov xwm txheej yuav tsum tsis txhob loj dhau, vim tias lub kaum sab xis siab heev tuaj yeem txo lub zog ntom ntom ntawm cov khoom siv, yog li ua kom tsis muaj peev xwm tu lub laser.

Muaj kev siv ntawm Laser Ntxuav:

1: Pwm Kev Lag Luam

Laser tu ua kom tsis muaj kev sib cuag rau cov pwm, ua kom muaj kev nyab xeeb ntawm pwm qhov chaw.Nws lav qhov tseeb thiab tuaj yeem ntxuav cov av me me me me uas cov txheej txheem tu ib txwm tuaj yeem tawm tsam kom tshem tawm.Qhov no ua tiav qhov tseeb tsis muaj kuab paug, ua haujlwm tau zoo, thiab kev tu kom zoo.

2: Precision Instrument Kev Lag Luam

Nyob rau hauv precision mechanical industries, cov khoom feem ntau yuav tsum muaj esters thiab ntxhia roj siv rau lubrication thiab corrosion kuj raug tshem tawm.Cov txheej txheem tshuaj feem ntau yog siv los ntxuav, tab sis feem ntau lawv tawm cov seem.Laser tu tuaj yeem tshem tawm cov esters thiab cov roj ntxhia tsis muaj kev puas tsuaj rau saum npoo ntawm cov khoom.Laser-induced explosions ntawm oxide txheej ntawm cov khoom nto ua rau poob siab tsis, ua rau tshem tawm cov kab mob tsis muaj kev cuam tshuam txhua yam.

3: Rail Kev Lag Luam

Tam sim no, kev tsheb ciav hlau tu ua ntej vuam feem ntau yog siv lub log sib tsoo thiab xuab zeb, ua rau muaj kev puas tsuaj loj hauv substrate thiab kev ntxhov siab.Tsis tas li ntawd, nws siv cov khoom siv abrasive tseem ceeb, uas ua rau cov nqi siab thiab muaj plua plav hnyav.Laser tu tuaj yeem muab cov txheej txheem zoo, ua haujlwm zoo, thiab ib puag ncig tus phooj ywg tu cov txheej txheem rau kev tsim cov tsheb ciav hlau ceev hauv Suav teb.Nws hais txog cov teeb meem xws li seamless rail qhov, grey me ntsis, thiab vuam tsis xws luag, txhim khu kev ruaj ntseg thiab kev nyab xeeb ntawm kev kub ceev railway kev khiav hauj lwm.

4: Kev lag luam dav hlau

Lub dav hlau nto yuav tsum tau repainted tom qab ib tug tej lub sij hawm, tab sis ua ntej painting, cov xim qub yuav tsum tau muab tshem tawm tag nrho.Chemical immersion / so yog ib txoj kev pleev xim tseem ceeb hauv kev lag luam aviation, ua rau cov tshuaj khib nyiab ntau heev thiab tsis muaj peev xwm ua tiav cov xim pleev xim hauv zos rau kev kho.Laser tu tuaj yeem ua tau zoo tshem tawm cov xim ntawm lub dav hlau ntawm daim tawv nqaij thiab yog yooj yim yoog mus rau automated ntau lawm.Tam sim no, cov thev naus laus zis no tau pib siv rau hauv kev saib xyuas ntawm qee cov qauv dav hlau high-end txawv teb chaws.

5: Maritime Kev Lag Luam

Kev tu ua ntej ua ntej hauv kev lag luam maritime feem ntau siv cov txheej txheem sandblasting, ua rau muaj plua plav hnyav rau ib puag ncig.Raws li sandblasting maj mam raug txwv, nws tau ua rau txo qis kev tsim khoom lossis txawm tias kaw rau cov tuam txhab tsim nkoj.Laser tu tshuab yuav muab cov tshuaj ntsuab thiab tsis muaj kuab paug rau kev tiv thaiv corrosion txheej ntawm lub nkoj nto.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。

Post lub sij hawm: Jan-16-2024