Cov Ntsiab Cai ntawm Laser Vuam

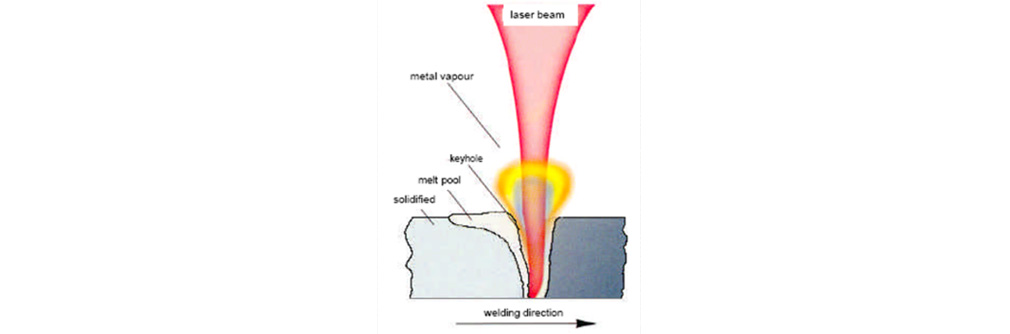

Laser vuamsiv cov kev taw qhia zoo heev thiab lub zog siab ceev cov yam ntxwv ntawm lub teeb laser ua haujlwm.Los ntawm ib qho kev kho qhov muag, lub teeb laser yog tsom rau ntawm thaj chaw me me, tsim kom muaj cov cua kub hauv lub sijhawm luv heev.Cov txheej txheem no melts cov khoom ntawm lub vuam taw tes, tsim ib tug solidified weld chaw thiab seam.

·Laser vuam yog feem ntau muab faib ua conduction vuam thiab sib sib zog nqus welding.

·Laser zog ceev ntawm 105~ 106w/cm2ua rau laser conduction vuam.

·Laser zog ceev ntawm 105~ 106w/cm2ua rau laser tob tob welding.

Cov yam ntxwv ntawm Laser Vuam

Piv rau lwm txoj kev vuam, laser vuam muaj cov yam ntxwv hauv qab no:

·Tsom ntsoov rau lub zog, siab vuam efficiency, siab ua precision, thiab ib tug loj qhov tob-rau-dav piv ntawm weld seam.

·Tsawg tshav kub input, me me tshav kub-tshem tawm tsam, tsawg residual kev nyuaj siab, thiab tsawg deformation ntawm lub workpiece.

·Kev sib txuas tsis sib cuag, fiber ntau optic kis tau tus mob, kev nkag tau zoo, thiab qib siab ntawm automation.

·Saj zawg zog sib koom tsim, txuag raw khoom.

·Vuam lub zog tuaj yeem tswj tau qhov tseeb, ua kom ruaj khov cov txiaj ntsig thiab vuam zoo.

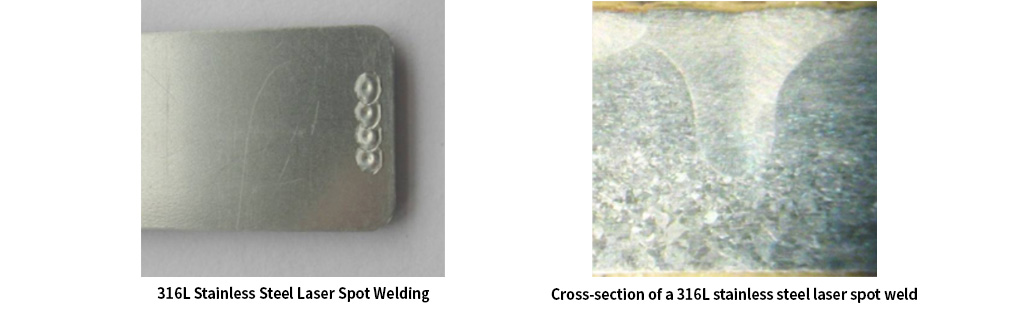

Vuam steel thiab nws cov alloys

·Stainless hlau tuaj yeem ua tiav cov txiaj ntsig zoo vuam siv tus qauv square yoj.

·Thaum tsim cov qauv welded, sim ua kom cov ntsiab lus vuam kom deb ntawm cov khoom tsis yog xim hlau ntau li ntau tau.

·Yuav kom ua tau raws li qhov yuav tsum tau muaj zog thiab zoo li yuav tsum tau, nws yog ib qho tsim nyog kom khaws cia qhov chaw vuam txaus thiab workpiece thickness.

·Thaum vuam, nws yog ib qho tseem ceeb los xyuas kom meej qhov huv ntawm lub workpiece thiab dryness ntawm ib puag ncig.

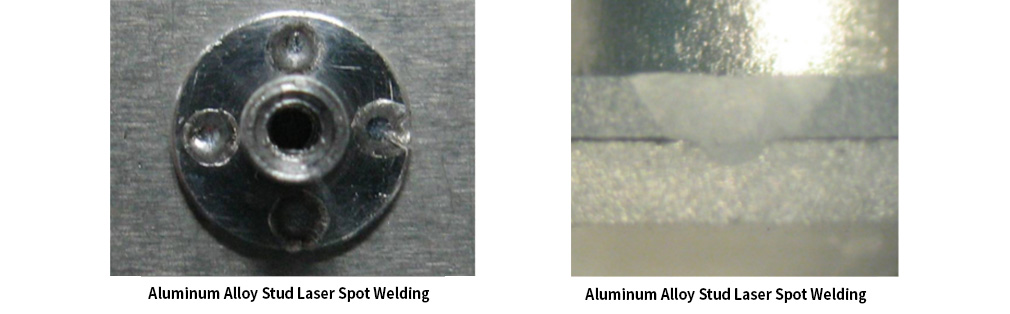

Vuam ntawm Aluminium thiab nws cov Alloys

·Cov ntaub ntawv aluminium alloy muaj qhov cuam tshuam siab;Yog li ntawd, yuav tsum muaj lub zog siab laser siab thaum lub sijhawm vuam.

·Kev tawg yooj yim tshwm sim thaum lub sij hawm pulse qhov chaw vuam, cuam tshuam rau lub zog vuam.

·Cov ntaub ntawv muaj pes tsawg leeg yog segregation, ua rau splattering.Nws raug nquahu kom xaiv cov khoom zoo raw khoom.

·Feem ntau, siv qhov chaw loj thiab ntev mem tes dav tuaj yeem ua tiav cov txiaj ntsig zoo dua.

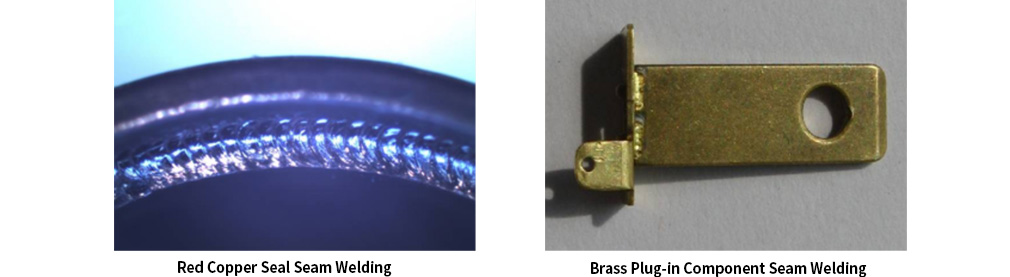

Vuam ntawm tooj liab thiab nws cov Alloys

·Cov ntaub ntawv tooj liab muaj qhov cuam tshuam ntau dua piv rau aluminium alloys, xav tau lub zog siab dua laser rau vuam.Lub taub hau laser yuav tsum tau tilted ntawm ib lub kaum ntse ntse.

·Rau qee qhov tooj liab alloys, xws li tooj dag thiab tooj liab, qhov nyuaj vuam yog nce vim muaj kev cuam tshuam ntawm cov ntsiab lus alloy.Kev saib xyuas yuav tsum tau them rau kev xaiv cov txheej txheem vuam tsis.

Qhov sib txawv ntawm Hlau Vuam

·Yuav tsim tau ib qho kev daws teeb meem.

·Puas muaj qhov sib txawv tseem ceeb hauv electronegativity ntawm cov hlau tsis sib xws.

·Lwm yam cuam tshuam.

Txawm hais tias cov hlau tsis sib xws tuaj yeem tsim cov khoom siv vuam zoo feem ntau yog nyob ntawm lub cev, cov khoom siv tshuaj, tshuaj muaj pes tsawg leeg, thiab cov txheej txheem ntsuas ntawm cov hlau yuav tsum tau welded.Qhov no feem ntau yog txiav txim siab los ntawm cov hauv qab no:

·Txawm hais tias qhov kev daws teeb meem tuaj yeem tsim tau nyob ntawm seb cov hlau tsis sib xws tuaj yeem sib koom ua ke hauv cov kua thiab cov khoom hauv lub xeev.Tsuas yog thaum lawv muaj peev xwm yaj nyob rau hauv ib leeg indefinitely, muaj zog thiab ruaj khov weld sib koom ua ke.Feem ntau, ib qho tseem ceeb solubility, los yog txawm unlimited solubility, yog ua tau tsuas yog thaum lub atomic radius sib txawv ntawm ob hlau yog tsawg dua li ntawm 14% mus rau 15%.

·Txawm hais tias muaj qhov sib txawv tseem ceeb hauv electronegativity ntawm cov hlau tsis sib xws kuj tseem ceeb heev.Qhov ntau dua qhov sib txawv, qhov muaj zog ntawm lawv cov tshuaj affinity, uas zoo li ua rau kev tsim cov tebchaw es tsis yog cov kev daws teeb meem.Yog li ntawd, lub solubility ntawm cov khoom tov uas tau tsim yog txo, thiab lub zog ntawm cov weld sib koom tes kuj qis dua.

·Tsis tas li ntawd, qhov vuam ntawm cov hlau tsis sib xws tau cuam tshuam zoo heev los ntawm cov khoom xws li cov ntsiab lus melting, coefficients ntawm thermal expansion, thermal conductivities, tshwj xeeb heats, oxidizability, thiab reflectivity ntawm cov ntaub ntawv koom nrog.Qhov ntau dua qhov sib txawv ntawm cov khoom ntawm lub cev, qhov nyuaj dua nws yog vuam, thiab qhov tsis muaj zog ntawm qhov tshwm sim weld sib koom ua ke.

·Feem ntau, laser vuam ntawm cov khoom siv hlau tsis sib xws xws li hlau nrog tooj liab, txhuas, thiab npib tsib xee, nrog rau tooj liab nrog npib tsib xee, nthuav tawm cov khoom zoo weldability, ua rau cov khoom siv vuam zoo.

Laser vuam pom kev siv dav hauv ntau qhov chaw, suav nrog tab sis tsis txwv rau thaj chaw hauv qab no:

1: Tsis sib xws Hlau Vuam

Laser vuam yog dav siv nyob rau hauv manufacturing industries xws li automotive, aerospace, electronics, thiab mechanical engineering.Nws yog siv rau vuam Cheebtsam thiab assembling lug, txhim khu ntau lawm efficiency thiab cov khoom zoo.

2: Cov khoom siv kho mob

Hauv kev tsim cov khoom siv kho mob, laser vuam yog siv rau kev sib txuas thiab sib sau ua ke me me, cov khoom siv tau zoo, ua kom cov khoom zoo thaum tsis txhob muaj kev kub ntxhov ntau dhau ntawm cov ntaub ntawv.

3: Electronics

Vim nws qhov siab precision thiab tsis tshua muaj cua sov input, laser vuam yog dav siv nyob rau hauv kev tsim cov khoom siv hluav taws xob, nrog rau cov Circuit Court welding thiab microelectronic Cheebtsam.

4: Aerospace UAS

Laser vuam yog siv nyob rau hauv lub aerospace sector rau tsim aircraft thiab aerospace Cheebtsam, enabling lub teeb yuag tsim thiab high-lub zog sib txuas.

5: Kev Siv Hluav Taws Xob

Hauv kev lag luam hluav taws xob, laser vuam yog ua haujlwm rau kev tsim cov hnub ci vaj huam sib luag, cov khoom siv hluav taws xob nuclear, thiab lwm yam khoom muaj feem xyuam rau kev tsim hluav taws xob.

6: Cov hniav nyiaj hniav kub thiab Watchmaking

Muab nws cov kev hloov pauv rau cov qauv zoo thiab tsis sib xws, laser vuam feem ntau yog siv rau hauv kev tsim cov hniav nyiaj hniav kub thiab saib rau kev sib txuas thiab kho cov khoom muag.

7: Automotive Kev Lag Luam

Hauv kev tsim tsheb, laser vuam yog ua haujlwm rau kev txuas cov khoom siv tsheb, txhim kho vuam efficiency, thiab txhim kho cov khoom zoo.

Zuag qhia tag nrho, qhov siab precision, ceev, thiab versatility ntawm laser vuam ua rau nws dav siv nyob rau hauv manufacturing thiab ntau lawm teb.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。

Post lub sij hawm: Jan-17-2024