Ụkpụrụ nke ịgbado ọkụ laser

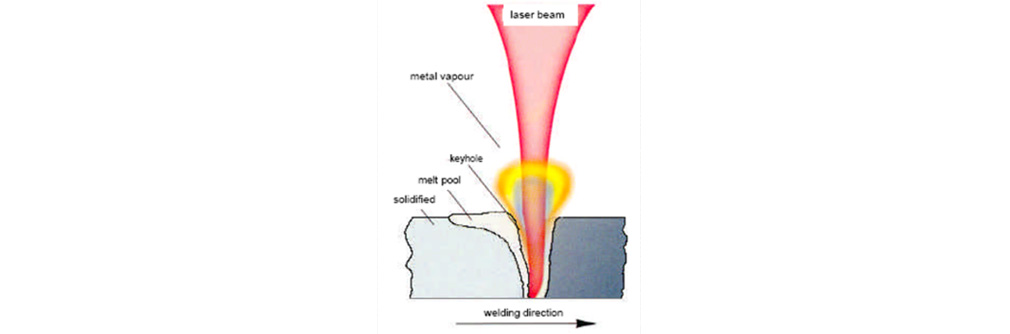

Mgbado ọkụ laserutilizes magburu onwe directional na elu ike njupụta àgwà nke a laser doo na-arụ ọrụ.Site na usoro anya, a na-elekwasị anya n'ọkụ laser na mpaghara dị ntakịrị, na-emepụta isi iyi ọkụ na-ekpo ọkụ na obere oge.Usoro a na-agbaze ihe ahụ na ebe ịgbado ọkụ, na-akpụ ntụpọ weld siri ike na ọnụ.

·A na-ekewa welding laser ka ọ bụrụ ịgbado ọkụ conduction na ịgbado ọkụ miri emi.

·Njupụta ike laser nke 105~106w/cm2na-arụpụta ịgbado ọkụ laser conduction.

·Njupụta ike laser nke 105~106w/cm2na-ebute ịgbado ọkụ laser miri emi.

Njirimara nke ịgbado ọkụ laser

E jiri ya tụnyere ụzọ ịgbado ọkụ ndị ọzọ, ịgbado ọkụ laser nwere njirimara ndị a:

·Ike lekwasịrị anya, arụmọrụ ịgbado ọkụ dị elu, nhazi nhazi dị elu, yana oke omimi ruo n'obosara nke eriri weld.

·Ntinye obere okpomọkụ, obere mpaghara okpomọkụ emetụtara, nrụgide dị ntakịrị, na nrụrụ dị ala nke workpiece.

·Ịgbado ọkụ na-abụghị kọntaktị, nnyefe fiber optic, nnweta dị mma, yana ọkwa dị elu nke akpaaka.

·Nhazi nkwonkwo na-agbanwe agbanwe, na-echekwa akụrụngwa.

·Enwere ike ịchịkwa ike ịgbado ọkụ nke ọma, na-eme ka nsonaazụ ịgbado ọkụ kwụsiri ike yana ọdịdị ịgbado ọkụ dị mma.

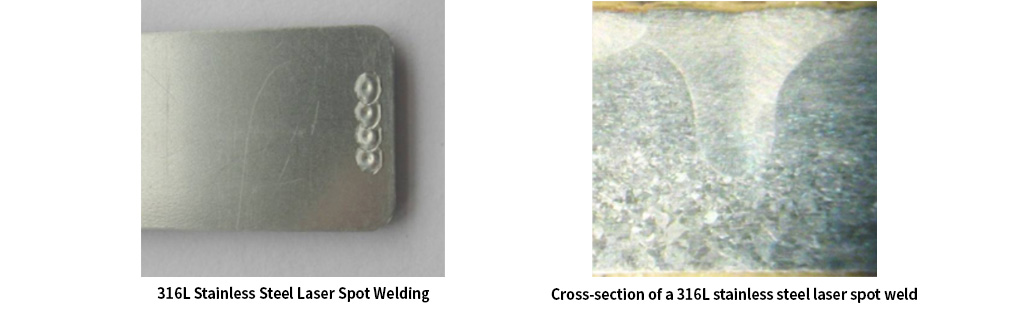

Welding nke Steel na Alloys ya

·Igwe anaghị agba nchara nwere ike nweta nsonaazụ ịgbado ọkụ dị mma site na iji ọkọlọtọ square ebili mmiri.

·Mgbe ị na-emebe ihe owuwu welded, gbalịa idobe isi weld pụọ na ihe ndị na-abụghị ọla dị ka o kwere mee.

·Iji mezuo ike na ọdịdị chọrọ, ọ bụ ihe amamihe dị na ya idowe ebe ịgbado ọkụ zuru oke na ọkpụrụkpụ workpiece.

·N'oge ịgbado ọkụ, ọ dị mkpa iji hụ na ịdị ọcha nke workpiece na nkụ nke gburugburu ebe obibi.

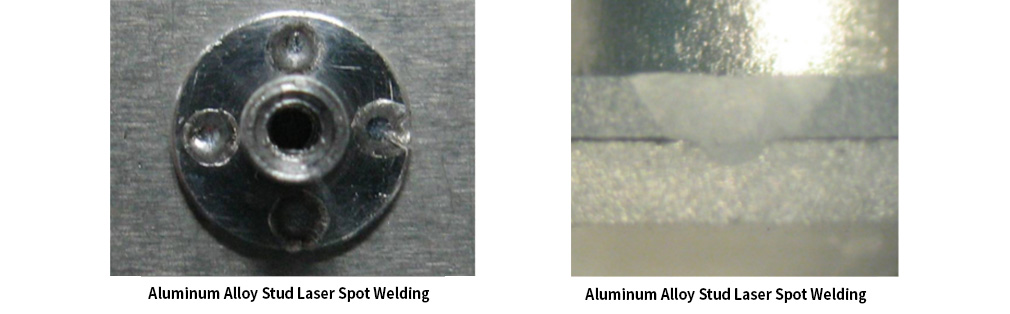

Welding nke Aluminom na Alloys ya

·Aluminom alloy ihe nwere nnukwu reflectivity;ya mere, a chọrọ ike elu laser dị elu n'oge ịgbado ọkụ.

·Ihe mgbawa na-adịkarị mfe ime n'oge ịgbado ọkụ ntụpọ usu, na-emetụta ike ịgbado ọkụ.

·Ngwakọta ihe eji eme ihe na-adịkarị mfe nkewa, na-eduga n'ịgbasa.Ọ bụ ihe amamihe dị na ya ịhọrọ akụrụngwa dị elu.

·N'ozuzu, iji nnukwu ntụpọ nha na ogologo usu obosara nwere ike nweta nsonaazụ ịgbado ọkụ ka mma.

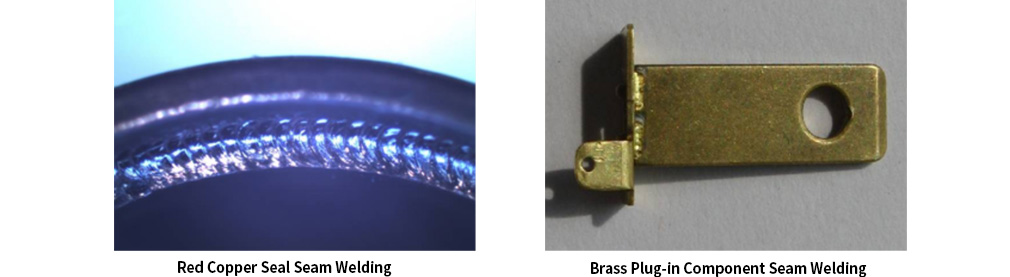

Welding nke ọla kọpa na Alloys ya

·Ihe ọla kọpa nwere ngosipụta dị elu ma e jiri ya tụnyere aluminum alloys, na-achọ ike laser kachasị elu maka ịgbado ọkụ.Ọ dị mkpa ka atụgharị isi laser n'otu akụkụ.

·Maka ụfọdụ alloys ọla kọpa, dị ka ọla na ọla kọpa, ihe isi ike ịgbado ọkụ na-abawanye n'ihi mmetụta nke ihe alloy.Ekwesịrị ilebara anya na nhọrọ nke usoro ịgbado ọkụ.

Mgbado igwe dị iche iche

·Enwere ike ịmepụta ngwọta siri ike.

·Enwere nnukwu ọdịiche dị na electronegativity n'etiti ọla ndị na-adịghị ahụkebe.

·Ihe ndị ọzọ na-emetụta.

Ma ụdị ọla ndị ahụ nwere ike ịmepụta nkwonkwo ịgbado ọkụ dị elu na-adabere na njirimara anụ ahụ, njirimara kemịkalụ, ihe mejupụtara kemịkalụ, na usoro nke ọla ndị a ga-agbado.A na-atụle nke a site na akụkụ ndị a:

·Ma enwere ike ịmepụta ngwọta siri ike na-adabere na ọla ndị na-adịghị ahụkebe nwere ike ịgbarikọ ọnụ na mmiri mmiri na steeti siri ike.Naanị mgbe ha nwere ike igbari n'ime ibe ha ruo mgbe ebighị ebi, enwere ike ịmepụta nkwonkwo siri ike ma sie ike.N'ozuzu, a dị ịrịba ama solubility, ma ọ bụ ọbụna na-akparaghị ókè solubility, bụ nke a ga-enweta naanị mgbe atomiki radius dị iche n'etiti ọla abụọ ahụ na-erughị ihe dịka 14% ruo 15%.

·Ma enwere nnukwu ọdịiche dị na electronegativity n'etiti ọla dị iche iche dịkwa oke mkpa.Ihe dị iche iche dị ukwuu, otú ahụ ka njikọ kemịkal ha na-esiwanye ike, nke na-eduga n'ịmepụta ogige karịa ngwọta siri ike.N'ihi ya, solubility nke ngwọta siri ike nke a na-emepụta na-ebelata, ike nke nkwonkwo weld dịkwa ala.

·Na mgbakwunye, ịgbado ọkụ nke ọla ndị yiri ya na-emetụta nke ukwuu site na akụrụngwa dị ka ebe mgbaze, ọnụọgụ nke mgbasawanye thermal, conductivities thermal, okpomoku akọwapụtara, oxidizability, na ngosipụta nke ihe ndị metụtara.Ka ọdịiche dị na akụrụngwa anụ ahụ ndị a dị ukwuu, ka ọ na-esiri ya ike ịgbado ọkụ, na ike nke nkwonkwo weld na-esi na ya pụta na-esiwanye ike.

·Ọtụtụ mgbe, ịgbado ọkụ laser nke ihe ọla dị iche iche dị ka ígwè nwere ọla kọpa, aluminom, na nickel, yana ọla kọpa nwere nickel, na-egosipụta ezigbo weldability, na-eduga n'ịdị mma ịgbado ọkụ na-eju afọ.

Mgbado ọkụ laser na-achọta ngwa dị ukwuu n'ofe mpaghara dị iche iche, gụnyere mana ọnweghị oke na mpaghara ndị a:

1: Mgbado igwe anaghị agba nchara

A na-arụ ọrụ ịgbado ọkụ laser na ụlọ ọrụ mmepụta ihe dị ka ụgbọ ala, ikuku ikuku, eletrọnịkị, na injinia.A na-eji ya eme ihe maka ịgbado ọkụ na ikpokọta ihe owuwu, na-eme ka nrụpụta mmepụta na ịdị mma ngwaahịa.

2: Ngwa ahụike

N'imepụta ngwaọrụ ahụike, a na-eji ịgbado ọkụ laser eme ihe maka ijikọ na ikpokọta obere ihe mejupụtara nkenke, na-ahụ na ngwaahịa dị elu ma na-ezere mmetụta dị oke ọkụ na ihe.

3: Eletrọnịkị

N'ihi nzizi ya dị elu na ntinye ọkụ dị ala, a na-etinye ịgbado ọkụ laser n'ọtụtụ ebe n'ichepụta ngwaọrụ eletrọnịkị, gụnyere ịgbado ọkụ bọọdụ sekit na ihe microelectronic.

4: Aerospace

A na-eji ịgbado ọkụ laser na mpaghara ikuku maka imepụta ụgbọ elu na akụrụngwa ikuku, na-eme ka imewe dị fechaa na njikọ dị elu.

5: Ngalaba Ike

N'ime ụlọ ọrụ ike, a na-arụ ọrụ ịgbado ọkụ laser maka imepụta ogwe ọkụ, akụrụngwa ike nuklia na ihe ndị ọzọ metụtara mmepụta ume.

6: Ọla na Ime nche

N'iburu ngbanwe ya na ihe owuwu dị mma ma dị mgbagwoju anya, a na-ejikarị ịgbado ọkụ laser eme ihe n'ichepụta ọla na elekere maka ijikọ na ịrụzi ihe ndị siri ike.

7: Ụlọ ọrụ ụgbọ ala

N'imepụta ụgbọ ala, a na-arụ ọrụ ịgbado ọkụ laser maka ijikọ akụrụngwa akpaaka, melite arụmọrụ ịgbado ọkụ, yana ịkwalite ogo ngwaahịa.

N'ozuzu, na elu nkenke, ọsọ, na versatility nke laser ịgbado ọkụ na-eme ka ọ n'ọtụtụ ebe ọdabara na n'ichepụta na mmepụta ubi.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。

Oge nzipu: Jan-17-2024