2 Axis Laser Galvo Scanner GO7 Series China

Kepala Scanner Galvo Laser 2D Presisi Tinggi kanthi Sumbu XY kanggo Penandaan Laser, Etsa, Ukiran, Pemotongan, Welding...

GO7 seri digital laser galvo scanner sirah iki dibukak dening JCZ ing 2016, karo rega competitive, stabilitas dhuwur, lan tingkat repair kurang, digunakake digunakake kanggo mesin laser kanggo menehi tandha, etching, engraving, welding, nglereni ...

Kanthi macem-macem ukuran pangilon opsional (8mm, 10mm, 12mm, 14mm, 16mm, 20mm ...) lan dilapisi dawa gelombang (355,532,1064,10600nm) kanggo laser kaya serat, CO2, YAG, UV, Ijo ...

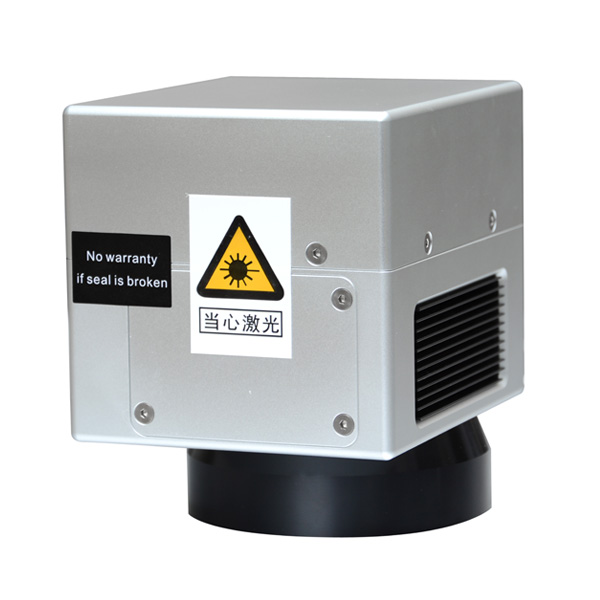

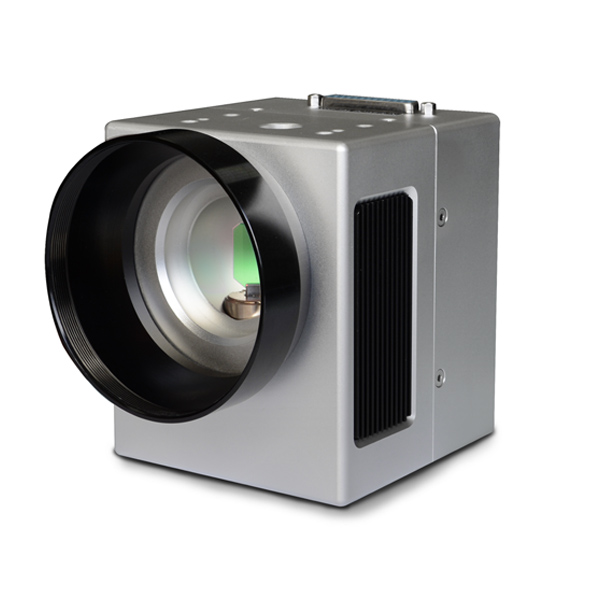

Gambar Produk

Pitakonan

1. lapisan Mirror: Laser beda mbutuhake mirrors ditutupi beda ing galvo laser.Biasane, 355nm kanggo laser UV, 532nm kanggo laser ijo, 1064nm kanggo YAG lan Fiber laser, 10600nm kanggo CO2 laser.Sinar laser ora bisa dibayangke yen dawa gelombang sing dilapisi ora cocog karo dawa gelombang laser.

2. Bukaan Input: Tegese ukuran bolongan galvo laser ing ngendi sinar laser mlebu. Beam sing ditambahi kudu padha karo ukuran bukaan input.Yen ukuran beam luwih gedhe tinimbang aperture input, iku bakal biaya sampah sinar laser.

Kita kabeh ngerti yen kacepetan luwih dhuwur, presisi luwih miskin.A imbangan antarane kacepetan lan tliti cukup penting.Ngomong teknis, 2000mm / s cukup kanggo menehi tandha normal, kanthi presisi sing apik.

Spesifikasi

| Model: | Seri GO7 | |||||

| Dawane gelombang | 355nm, 532nm, 1064nm, 10600nm... | |||||

| Antarmuka | XY2-100 | |||||

| Bukaan Input (mm) | 8 | 10 | 12 | 14 | 16 | 20 |

| Kinerja Dinamis | ||||||

| Wektu kesalahan nelusuri (ms) | 0.18 | 0,22 ms | 0.36 | 0.38 | 0.4 | 0.4 |

| Repeatability (urad) | <22 | <22 | <22 | <22 | <22 | <22 |

| Gaindrift (ppm/K) | 80 | 80 | 80 | 80 | 80 | 80 |

| Offsetdrift(urad/K) | 30 | 30 | 30 | 30 | 30 | 30 |

| 1% saka skala lengkap (ms) | 0.25 | 0.3 | 0.4 | 0.65 | 0.7 | 0.8 |

| 10% saka skala lengkap (ms) | 0.7 | 0.8 | 1.2 | 1.6 | 1.7 | 1.8 |

| Non-Linearitas (mrad) | <0.9 | <0.9 | <0.9 | <0.9 | <0.9 | <0.9 |

| Drift jangka panjang luwih saka 8 jam (mrad) | <0.3 | <0.3 | <0.3 | <0.3 | <0.3 | <0.3 |

| Kacepetan khas | ||||||

| Kacepetan menehi tandha (mm/s) | 4000 | 3000 | 2500 | 2200 | 2000 | 1300 |

| Kacepetan posisi (m/s) | 15 | 12 | 10 | 8 | 7 | 6 |

| Kinerja Optik | ||||||

| Defleksi tipikal (rad) | ± 0,39 | ± 0,39 | ± 0,39 | ± 0,39 | ± 0,39 | ± 0,39 |

| Gain error (mrad) | <5 | <5 | <5 | <5 | <5 | <5 |

| Nol Offset (mrad) | <5 | <5 | <5 | <5 | <5 | <5 |

| Suhu operasi (℃) | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 | 10-40 |

| Suhu panyimpenan (℃) | -20-60 | -20-60 | -20-60 | -20-60 | -20-60 | -20-60 |

| Keperluan Daya | ± 15VDC, 3A | ± 15VDC, 3A | ± 15VDC, 3A | ± 15VDC, 3A | ± 15VDC, 3A | ± 15VDC, 3A |

| Bobot (kg) | 1.5 | 1.9 | 2 | 2.4 | 2.6 | 4.3 |