Nheyo dzeLaser Welding

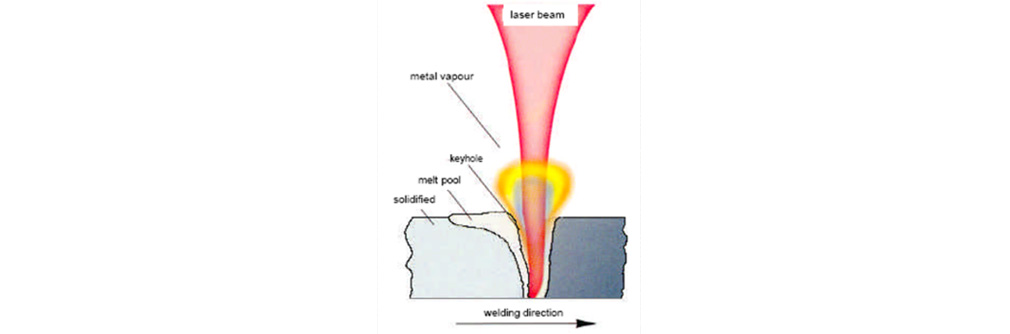

Laser weldinginoshandisa yakanakisa kutungamira uye yakakwirira simba density maitiro eiyo laser danda kushanda.Kuburikidza neiyo optical system, iyo laser beam inotariswa pane diki diki, ichigadzira yakanyanya kunyura kupisa sosi munguva pfupi.Iyi nzira inonyungudutsa zvinhu panzvimbo yewelding, ichigadzira yakaomeswa weld nzvimbo uye musono.

·Laser welding kazhinji yakakamurwa kuita conduction welding uye yakadzika yekupinda welding.

·A laser simba density ye105~106w/cm2inoguma nelaser conduction welding.

·A laser simba density ye105~106w/cm2inoguma nelaser deep penetration welding.

Hunhu hweLaser Welding

Kuenzaniswa nedzimwe nzira dzekushongedza, laser welding ine zvinotevera maitiro:

·Simba rakatarisana, kukwirira kwewelding, yakakwira kugadzirisa, uye yakakura kudzika-kusvika-kufara reshiyo ye weld seam.

·Kupisa kwakadzika kupinza, diki kupisa-kukanganisa nzvimbo, kushoma kusara kunetseka, uye kuderera deformation yeworkpiece.

·Non-contact welding, fiber optic transmission, kuwanikwa kwakanaka, uye yakakwirira mwero we automation.

·Flexible joint design, kuchengetedza mbishi zvinhu.

·Welding simba rinogona kunyatsodzorwa, kuve nechokwadi chakagadzikana welding mhedzisiro uye yakanaka welding kutaridzika.

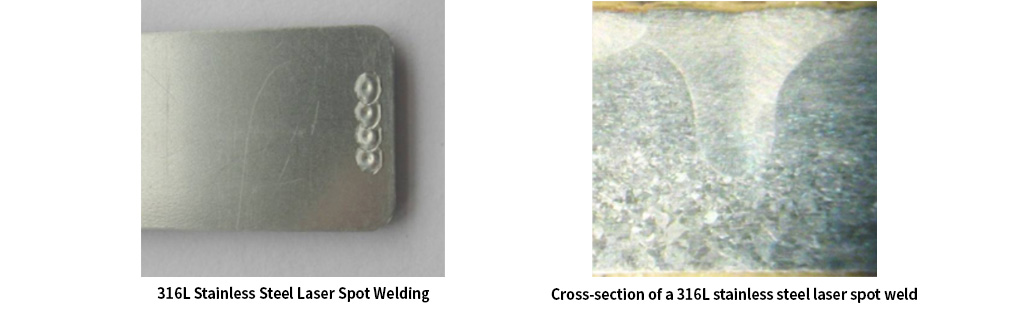

Welding yeSimbi uye maAlloys ayo

·Simbi isina tsvina inogona kuwana yakanaka welding mhedzisiro uchishandisa yakajairwa square wave.

·Paunenge uchigadzira zvimiro zvakashongedzwa, edza kuchengetedza weld point kubva kune zvisiri-metal zvinhu zvakanyanya sezvinobvira.

·Kuti usangane nesimba uye chitarisiko chinodiwa, zvinokurudzirwa kuchengetedza yakakwana welding nzvimbo uye workpiece ukobvu.

·Munguva yewelding, zvakakosha kuve nechokwadi chekuchena kweiyo workpiece uye kuoma kwenzvimbo.

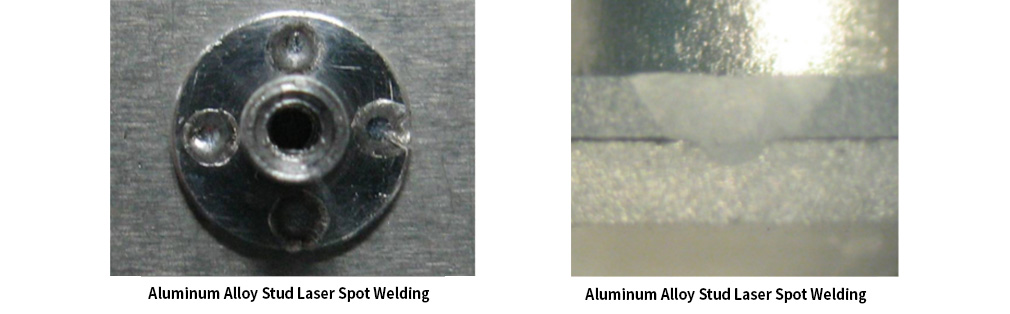

Welding yeAluminium uye maAlloys ayo

·Aluminium alloy zvinhu zvine yakakwirira reflectivity;saka, yakakwirira laser peak simba inodiwa panguva welding.

·Kutsemuka kunowanzo kuitika panguva yepulse spot welding, zvichikanganisa simba rekushongedza.

·Iko kuumbwa kwezvinhu kunowanzoita kupatsanurwa, zvichiita kuti splattering.Zvinokurudzirwa kusarudza yakakwirira-mhando mbishi zvinhu.

·Kazhinji, kushandisa saizi yakakura uye yakareba pulse hupamhi inogona kuwana zvirinani welding mhedzisiro.

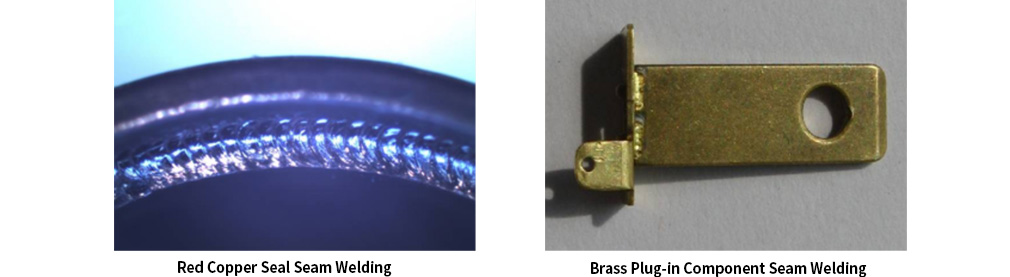

Welding yeMhangura uye maAlloys ayo

·Zvishandiso zvemhangura zvine ratidziro yepamusoro kana ichienzaniswa nealuminium alloys, inoda yepamusoro peak laser simba rewelding.Musoro welaser unoda kutenderedzwa pane imwe kona.

·Kune mamwe maalloys emhangura, akadai sendarira nebhuronzi, kuoma kwewelding kunowedzera nekuda kwesimba realloy elements.Kuchenjerera kunofanira kubhadharwa kune kusarudzwa kwewelding process parameters.

Dissimilar Metal Welding

·Ko mhinduro yakasimba inogona kuumbwa.

·Pane musiyano wakakura here mu electronegativity pakati pesimbi dzakasiyana.

·Zvimwe zvinofurira.

Kuti simbi dzakasiyana-siyana dzinogona kuumba majoini emhando yepamusoro-soro zvakanyanya zvinoenderana nehunhu hwemuviri, zvimiro zvemakemikari, kuumbwa kwemakemikari, uye magadzirirwo emasimbi anoiswa weld.Izvi zvinonyanya kutariswa kubva kune zvinotevera zvikamu:

·Kuti mhinduro yakasimba inogona kuumbwa zvinoenderana nekuti simbi dzisina kufanana dzinogona kunyungudika mumvura uye dzakasimba nyika.Chete apo vanogona kunyungudika mune mumwe nemumwe nekusingaperi, yakasimba uye yakasimba weld joint inogona kuumbwa.Kazhinji, kunyungudika kwakakosha, kana kunyungudika kusingagumi, kunokwanisika chete kana musiyano weatomu yeradius pakati pemasimbi maviri uri pasi peinoda kusvika 14% kusvika 15%.

·Kana paine mutsauko wakakura mukufambiswa kwemagetsi pakati pesimbi dzakasiyana kwakakosha zvakare.Kunyanya mutsauko, kusimba kwavo kwemakemikari affinity, ayo anowanzo tungamira mukuumbwa kwemakomponi pane kugadzirisa kwakasimba.Somugumisiro, kunyungudika kwechigadziro chakasimba chinoumbwa chinoderedzwa, uye simba rekubatana kwe weld zvakare rakaderera.

·Pamusoro pezvo, kukwenenzverwa kwesimbi dzakasiyana kunokanganisa zvakanyanya nezvivakwa zvakaita senge mapoinzi ekunyungudika, coefficients ekuwedzera kwemafuta, thermal conductivities, chaiyo kupisa, oxidizability, uye kuratidza kwezvinhu zvinosanganisirwa.Kunyanya mutsauko wezvinhu izvi zvemuviri, zvinonyanya kunetsa kuti weld, uye kushomeka kwesimba rezvinokonzeresa weld joint rinowanzova.

·Kazhinji, laser welding yezvakasiyana simbi zvinhu zvakaita sesimbi nemhangura, aruminiyamu, uye nickel, pamwe nemhangura ine nickel, inoratidzira yakanaka weldability, zvichitungamira kune inogutsa welding mhando.

Laser welding inowana maapplication akakura munzvimbo dzakasiyana siyana, kusanganisira asi isina kuganhurirwa kune dzinotevera nzvimbo:

1: Dissimilar Metal Welding

Laser welding inoshandiswa zvakanyanya mumaindasitiri ekugadzira akadai semota, aerospace, zvemagetsi, uye mechanic engineering.Iyo inoshandiswa kune welding zvikamu uye kuunganidza zvimiro, inosimudzira kugadzirwa kwakanaka uye mhando yechigadzirwa.

2: Zvishandiso zvekurapa

Mukugadzira michina yekurapa, laser welding inoshandiswa kubatanidza uye kuunganidza zvidiki, zvakaringana zvikamu, kuve nechokwadi chezvigadzirwa zvemhando yepamusoro uku uchidzivirira kupisa kwakanyanya pazvinhu.

3: Zvemagetsi

Nekuda kwekunyanya kwayo uye yakaderera kupisa kwekuisa, laser welding inoshandiswa zvakanyanya mukugadzira zvigadzirwa zvemagetsi, zvinosanganisira redunhu bhodhi welding uye microelectronic zvikamu.

4: Muchadenga

Laser welding inoshandiswa munharaunda yeaerospace yekugadzira ndege uye zvikamu zvemuchadenga, zvichiita kuti dhizaini yakareruka uye kubatanidza kwakasimba.

5: Energy Sector

Muindasitiri yesimba, laser welding inoshandiswa kugadzira solar panels, midziyo yemagetsi enyukireya, uye zvimwe zvinhu zvine chekuita nekugadzirwa kwesimba.

6: Zvishongo uye Kugadzira wachi

Tichifunga nezvekuchinjika kwayo kune yakanaka uye yakaoma zvimiro, laser welding inowanzoshandiswa mukugadzira zvishongo nemawachi ekubatanidza nekugadzirisa zvinhu zvisina kusimba.

7: Indasitiri yemotokari

Mukugadzira mota, laser welding inoshandiswa kubatanidza zvinhu zvemotokari, kuvandudza kugona kwewelding, uye kuwedzera kunaka kwechigadzirwa.

Pakazere, iko kurongeka kwepamusoro, kumhanya, uye kuita kwakasiyana-siyana kwelaser welding kunoita kuti ishande zvakanyanya mukugadzira nekugadzira minda.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。

Nguva yekutumira: Jan-17-2024