Xalka dusha sare ee Laser Etching of Battery Electrode Sheets

Iyada oo ay sii kordhayaan shuruudaha soo-saarka automation-ka warshadaha iyo sirdoonka ee Shiinaha, Tiknoolajiyada xakamaynta laser-ka ayaa si joogto ah u cusbooneysiinaysa oo kor u qaadaysa, farsamaynta laysarka waa sifooyin processing aad u fiican ayaa si ballaaran loogu dabaqay dhinacyo kala duwan.

In wax soo saarka iyo habka wax soo saarka ee baytariyada, technology processing laser waxaa loo isticmaalaa in ka badan iyo marxalado badan, Laser waxay noqotay tignoolajiyada wax ku oolka badan ee dhimista kharashaadka iyo kordhinta waxtarka wax soo saarka batteriga.

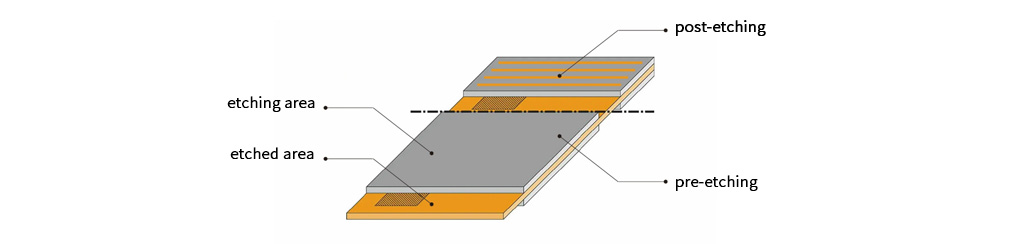

Si loo hagaajiyo waxqabadka batteriga, In wax soo saarka iyo habka wax soo saarka ee xaashida electrode batari, Habka wax soo saarka ee etching laser isticmaalaya technology calaamadaynta laser on lakabka daahan ee xaashida electrode batari. Habkani wuxuu si isku mid ah u dhejiyaa dahaarka labada dhinac ee xaashida elektiroonigga ah, isaga oo samaynaaya xariijimo qoto dheer oo qotodheer lakabka daahan ee xaashida korantada.

Ka-hortagga Laser-ku waa hab habaysan oo aan xidhiidh la lahayn oo aan sababayn cillad farsamo ee xaashida elektiroonigga ah ee baytariga, Hababka cabbirka habka layserka dabacsan ee rogrogmi kara waxay la kulmi kartaa qoto dheer oo kala duwan iyo shuruudaha dhererka.Habaynta laser-ku waa mid aad wax ku ool u ah oo la jaan qaadi karta xawaaraha alaabta gariiradda-ilaa-gariiradda, taas oo awood u siinaysa habaynteeda in-duulida.

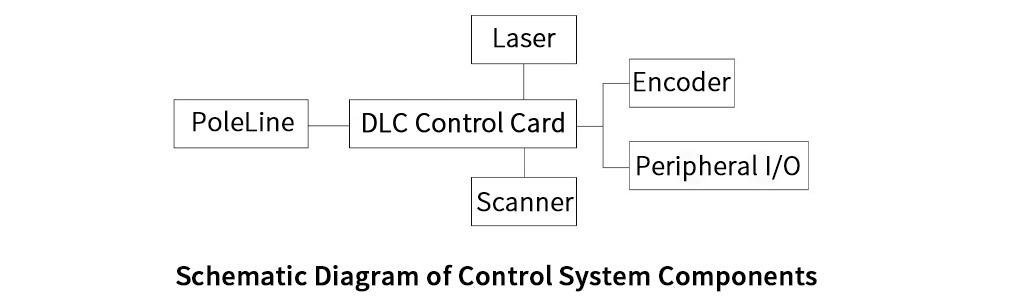

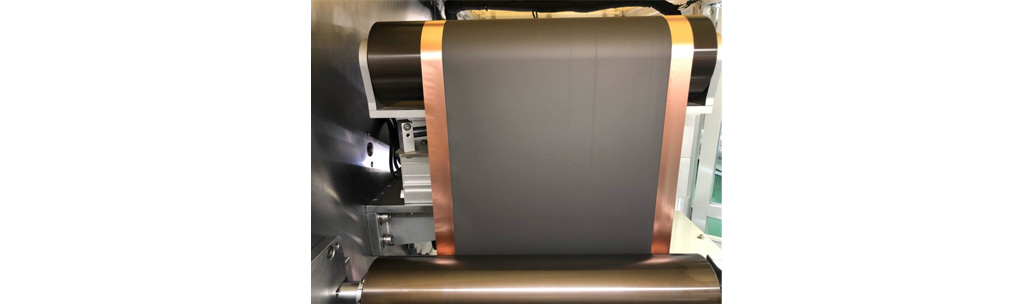

Tiknoolajiyada JCZ waxay leedahay khibrad qoto dheer oo ku saabsan xakamaynta muraayadda laysarka waxayna si fiican u baratay dhowr tignoolajiyada patented iyo khibrad codsi farsamaynta laser qani ah oo ku saabsan farsamaynta laser batteriga. Iyada oo taas ku saleysan, Tignoolajiyada JCZ waxay bilawday Nidaamka Hagaajinta Khadka Electrode si gaar ah loogu talagalay codsiga dusha laysarka ee xaashida elektiroonigga ah.

Astaamaha Muhiimka ah

Madax-madax badan oo duullimaadyo isku mid ah, oo leh kontorool ilaa 32galvohababka.

Habaynta xawaaraha socodka ee la qabsiga ah si loo hubiyo kala dheeraynta khadka wanaagsan iyo kala qaybinta saxnaanta ee qaabka xawaaraha doorsooma.

Taageerada qaababka kala duwan ee xaashida daahan electrode oo ay ku jiraan MMT/ASC/USC/SFC.

Taageerada shaqada qufulka booska dahaarka.

Taageer ka fogaanshaha booska, taageer xeerar kala duwan.

Farsamooyinka Muhiimka ah

Tiknoolajiyada xakameynta duulimaadka ee madax-badan

Algorithm magdhaw firfircooni leh oo si madaxbanaan u horumaray iyo tignoolajiyada xakamaynta muraayadaha badan, taageeridda habaynta kala qaybinta magdhowga ee boosaska dhaqdhaqaaqa xawaaraha doorsoomayaasha muraayadaha badan.

Tiknoolajiyada hagaajinta muraayadda saxda ah ee saxda ah

Muujinaya shaqada is-habaynta dhibco badan, oo u oggolaanaysa isticmaaleyaasha inay u habeeyaan dhibcaha cabbirka hagaajinta qallooca muraayadda, oo leh saxnaanta cabbirka muraayadda waji-buuxa oo sare oo gaadhaysa ilaa±10um (250*250 mm aagga).

Tignoolajiyada xakamaynta laser-ka

Xakamaynta leysarka oo dhamaystiran, taageerta kontoroolka leysarka caadiga ah, heerka laysarka iyo la socodka awooda, iyo magdhowga jawaab celinta awooda.

Tignoolajiyada magdhowga leexinta

Iyada oo ku saleysan leexinta dareeraha-la ogaaday macluumaadka xaashida korantada, xakamaynta magdhowga wakhtiga dhabta ah ee muraayadda ee xaashida korantada Y-jihada booska, hubinta meelaynta saxda ah ee xariiqyada xardhan.

以上内容主要来自于金橙子科技,部分素材来源于网络

Waqtiga boostada: Dec-29-2023