Theknoloji ea ho hloekisa ka laser e sebelisa bophara bo moqotetsane ba pulse, lasers ea matla a phahameng holim'a ntho e lokelang ho hloekisoa.Ka litlamorao tse kopantsoeng tsa ho sisinyeha ka potlako, mouoane, ho bola, le ho ebola ha plasma, litšila, mafome a mafome, kapa masela a holim'a metsi a fetoha mouoane hang-hang le ho arohana, ho fihlela tlhoekiso ea bokaholimo.

Ho hloekisa ka laser ho fana ka melemo e kang ho se kopane, ho boloka tikoloho, ho sebetsa hantle, 'me ha ho na tšenyo ho substrate, ho etsa hore e sebetse maemong a fapaneng.

Ho hloekisa Laser

Botala le bo sebetsang hantle

Indasteri ea lithaere, indasteri ea matla a macha, le indasteri ea mechini ea kaho, har'a tse ling, li sebelisa haholo ho hloekisa ka laser.Nakong ea lipheo tsa "dual carbon", ho hloekisa ka laser ho hlaha e le tharollo e ncha 'marakeng oa setso oa ho hloekisa ka lebaka la ts'ebetso ea ona e phahameng, taolo e nepahetseng, le litšobotsi tse baballang tikoloho.

Khopolo ea ho hloekisa Laser:

Ho hloekisoa ka laser ho kenyelletsa ho tsepamisa maballo a laser holim'a thepa hore e be mouoane ka potlako kapa e tlose litšila tse holim'a metsi, ho fihlela tlhoekiso ea lintho tse bonahalang.Ha ho bapisoa le mekhoa e fapaneng ea ho hloekisa ea 'mele kapa ea lik'hemik'hale, ho hloekisa ka laser ho khetholloa ka ho se kopane, ha ho lisebelisoa, ha ho na tšilafalo, ho nepahala ho phahameng, le tšenyo e fokolang kapa e se nang letho, e leng se etsang hore e be khetho e nepahetseng bakeng sa moloko o mocha oa theknoloji ea ho hloekisa indasteri.

Molao-motheo oa ho hloekisa Laser:

Molao-motheo oa ho hloekisa ka laser o rarahane 'me o ka kenyelletsa mekhoa ea' mele le ea lik'hemik'hale.Maemong a mangata, ts'ebetso ea 'mele e laola, e tsamaisana le liphetoho tse sa fellang tsa lik'hemik'hale.Mekhoa ea mantlha e ka aroloa ka mefuta e meraro: ts'ebetso ea mouoane, ts'ebetso ea ts'oenyeho, le ts'ebetso ea oscillation.

Mokhoa oa ho Fetola Gasification:

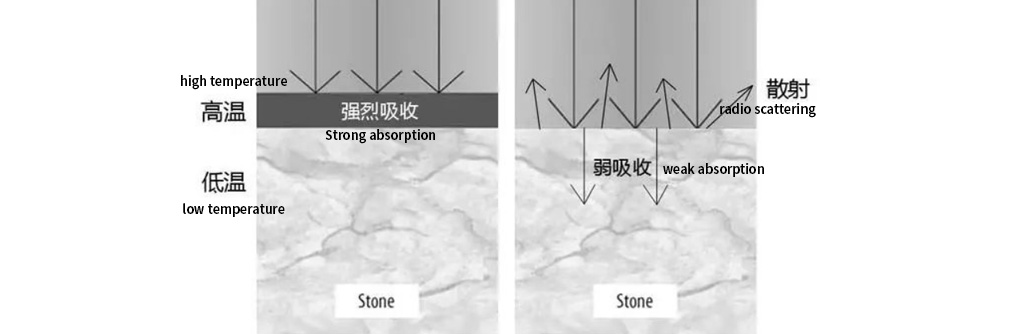

Ha mahlaseli a laser a nang le matla a phahameng a sebelisoa holim'a thepa, bokaholimo bo monya matla a laser ebe o a fetola matla a ka hare, e leng se etsang hore mocheso o holim'a metsi o eketsehe ka potlako.Ho phahama hona ha mocheso ho fihla kapa ho feta mocheso oa mouoane oa thepa, e leng se etsang hore litšila li hane ho tloha holim'a thepa ka mokhoa oa mouoane.Mouoane o khethehileng hangata o etsahala ha sekhahla sa ho monya ha litšila ho laser se phahame haholo ho feta sa substrate.Mohlala o tloaelehileng oa kopo ke ho hloekisa litšila holim'a majoe.Joalokaha ho bontšitsoe setšoantšong se ka tlase, litšila tse holim'a lejoe la majoe li monya laser ka matla 'me ka potlako li fufuleloa.Hang ha litšila li tlosoa ka ho feletseng, 'me laser e khantša holim'a lejoe, ho monya hoa fokola,' me matla a mangata a laser a hasane ka holim'a lejoe.Ka lebaka leo, ho na le phetoho e fokolang mocheso oa holim'a lejoe, ka tsela eo ho e sireletsa ho senya.

Ts'ebetso e tloaelehileng haholo-holo e amanang le ts'ebetso ea lik'hemik'hale e etsahala ha ho hloekisoa litšila tsa tlhaho ka li-laser tsa ultraviolet wavelength, mokhoa o tsejoang e le laser ablation.Li-laser tsa ultraviolet li na le maqhubu a makhutšoane le matla a phahameng a photon.Ka mohlala, KrF excimer laser e nang le leqhubu la 248 nm e na le matla a photon a 5 eV, e leng makhetlo a 40 ho feta CO2 laser photons (0.12 eV).Matla a joalo a phahameng a photon a lekane ho roba maqhama a limolek'hule linthong tsa manyolo, a etsa hore CC, CH, CO, joalo-joalo, litlamo tsa litšila tsa manyolo li robehe ha li monya matla a foto ea laser, e lebisang ho pyrolytic gasification le ho tlosoa bokahodimo.

Ts'ebetso ea Shock ka ho Hloekisa Laser:

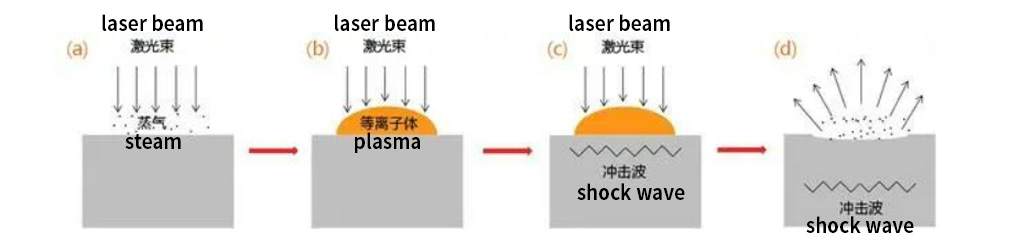

Ts'ebetso ea ts'oaetso ea ho hloekisa ka laser e kenyelletsa letoto la karabelo e etsahalang nakong ea tšebelisano lipakeng tsa laser le thepa, e bakang maqhubu a ts'oenyeho a amang bokaholimo ba thepa.Ka tlas'a tšusumetso ea maqhubu ana a ts'oenyehileng, litšila tse holim'a metsi li pshatleha hore e be lerōle kapa likotoana, li ebola ho tloha holimo.Mekhoa e bakang maqhubu ana a ts'oenyeho e fapane, ho kenyelletsa le plasma, mouoane, le liketsahalo tse potlakileng tsa ho ata le ho honyela ha mocheso.

Ho nka mohlala oa maqhubu a tšoso ea plasma, re ka utloisisa ka bokhutšoanyane hore na ts'ebetso ea ts'oaetso ea laser e tlosa litšila tse holim'a metsi joang.Ka ts'ebeliso ea li-laser tsa Ultra-short pulse wide (ns) le matla a holimo-limo (107– 1010 W/cm2) lasers, mocheso o ka holimo o ka nyoloha haholo ho ea ho mocheso oa mouoane le haeba ho monya ha laser ho fokola.Keketseho ena e potlakileng ea mocheso e etsa mouoane ka holim'a bokaholimo ba thepa, joalo ka ha ho bontšitsoe setšoantšong (a).Thempereichara ea mouoane e ka fihla ho 104 - 105 K, e lekaneng ho kenya mouoane ka boeona kapa moea o potolohileng, ho etsa plasma.Plasma e thibela laser hore e se ke ea fihla holim'a lintho tse bonahalang, mohlomong e emisa mouoane holim'a metsi.Leha ho le joalo, plasma e ntse e tsoela pele ho monya matla a laser, e eketsa mocheso oa eona le ho etsa boemo ba sebaka sa mocheso o phahameng haholo le khatello.Sena se hlahisa tšusumetso ea nakoana ea 1-100 kbar holim'a thepa mme e fetela ka hare butle-butle, joalo ka ha ho bontšoa litšoantšong (b) le (c).Ka tlas'a tšusumetso ea leqhubu la ts'isinyeho, litšila tse ka holimo li robeha ho ba lerōle le lenyenyane, likaroloana kapa likotoana.Ha laser e tloha sebakeng se khantšitsoeng, plasma e nyamela hang-hang, e baka khatello e mpe ea sebaka seo, 'me likaroloana kapa likaroloana tsa litšila li tlosoa holimo, joalokaha ho bontšitsoe papisong (d).

Mokhoa oa Oscillation ka Laser Cleaning:

Ts'ebetsong ea oscillation ea ho hloekisa ka laser, ho futhumatsa le ho pholile ha thepa ho etsahala ka potlako haholo tlas'a tšusumetso ea li-lasers tse khutšoanyane.Ka lebaka la li-coefficients tse fapaneng tsa katoloso ea mocheso oa lisebelisoa tse fapaneng, litšila tse holim'a metsi le substrate li na le katoloso e phahameng ea maqhubu a mocheso le ho honyela ha likhato tse fapaneng ha li pepesetsoa mahlaseli a leqhubu a lekhuts'oane.Sena se lebisa ho phello ea oscillatory e etsang hore litšila li fokotsehe holim'a lintho tse bonahalang.

Nakong ea ts'ebetso ena ea ho ebola, mouoane oa lintho tse bonahalang o ka 'na oa se ke oa etsahala, leha e le hore plasma ha ea thehoa.Ho e-na le hoo, ts'ebetso e itšetlehile ka matla a ho kuta a hlahisoang ho sehokelo pakeng tsa litšila le substrate tlas'a ketso ea oscillatory, e senyang maqhama pakeng tsa bona.Liphuputso li bonts'itse hore ho eketseha ha sekhahla ha sekhahla sa sekhahla sa sekhahla sa laser ho ka matlafatsa kamano pakeng tsa laser, litšila tse nang le likaroloana, le sebopeho sa substrate.Mokhoa ona o theola monyako oa ho hloekisa ka laser, o etsa hore phello ea oscillatory e hlahelle le ho ntlafatsa katleho ea ho hloekisa.Leha ho le joalo, angle ea liketsahalo ha ea lokela ho ba khōlō haholo, kaha angle e phahameng haholo e ka fokotsa matla a matla a sebetsang holim'a lintho tse bonahalang, kahoo a fokolisa matla a ho hloekisa a laser.

Lisebelisoa tsa indasteri ea ho hloekisa ka laser:

1: Indasteri ea Mold

Ho hloekisa ka laser ho etsa hore ho se ke ha kopana le hlobo bakeng sa hlobo, ho netefatsa polokeho ea bokaholimo ba hlobo.E netefatsa ho nepahala 'me e ka hloekisa likaroloana tsa litšila tsa sub-micron-level tseo mekhoa ea setso ea ho hloekisa e ka bang thata ho li tlosa.Sena se finyella tlhoekiso ea 'nete e se nang tšilafalo, e sebetsang hantle le ea boleng bo holimo.

2: Indasteri ea Lisebelisoa tsa Precision

Liindastering tse nepahetseng tsa mochini, hangata likarolo li hloka hore li-esters le oli ea liminerale e sebelisoe bakeng sa ho tlotsa le ho thibela kutu.Mekhoa ea lik'hemik'hale e atisa ho sebelisoa bakeng sa ho hloekisa, empa hangata e siea mesaletsa.Ho hloekisa ka laser ho ka tlosa ka ho feletseng li-esters le oli ea diminerale ntle le ho senya bokaholimo ba likarolo.Ho phatloha ho bakoang ke laser ea likarolo tsa oxide holim'a likarolo tsa likarolo ho etsa hore ho be le maqhubu a tšosang, a bakang ho tlosoa ha litšila ntle le ho sebelisana ha mechine.

3: Indasteri ea Terene

Hajoale, ho hloekisa seporo pele ho tjheseletsa ho sebelisoa haholo ho sila le mabili le sanding, ho lebisang tšenyong e matla ea substrate le khatello e setseng.Ho feta moo, e sebelisa lisebelisoa tse ngata tse senyang, tse bakang litšenyehelo tse phahameng le tšilafalo e tebileng ea lerōle.Ho hloekisa ka laser ho ka fana ka mokhoa oa ho hloekisa oa boleng bo holimo, o sebetsang hantle, le o baballang tikoloho bakeng sa tlhahiso ea liporo tsa terene tse lebelo haholo China.E sebetsana le litaba tse kang likoti tse se nang moroallo, libaka tse pherese, le bofokoli ba ho cheselletsa litšepe, ho matlafatsa botsitso le polokeho ea tšebetso ea liporo tsa lebelo le holimo.

4: Indasteri ea Lifofane

Libaka tsa lifofane li hloka ho penta bocha ka mor'a nako e itseng, empa pele ho penta, pente ea khale e tlameha ho tlosoa ka ho feletseng.Ho qoelisoa ka lik'hemik'hale / ho hlakola ke mokhoa o moholo oa ho tlosa pente lefapheng la lifofane, o bakang litšila tse ngata tsa lik'hemik'hale le ho sitoa ho finyella ho tlosoa ha pente sebakeng sa heno bakeng sa tlhokomelo.Ho hloekisa ka laser ho ka finyella ho tlosoa ha pente ea boleng bo phahameng holim'a letlalo la sefofane 'me ho bonolo ho ikamahanya le tlhahiso ea mochine.Hona joale, theknoloji ena e qalile ho sebelisoa ho boloka mefuta e meng ea lifofane tsa maemo a holimo linaheng tse ling.

5: Indasteri ea Maritime

Ho hloekisa pele ho tlhahiso indastering ea maoatle hangata ho sebelisa mekhoa ea ho qhomisa lehlabathe, e bakang tšilafalo e matla ea lerōle tikolohong e haufi.Kaha ho phatloha ha lehlabathe ho ntse ho thibetsoe butle-butle, ho lebisitse ho fokotseng tlhahiso kapa esita le ho koaloa ha lik'hamphani tse ahang likepe.Theknoloji ea ho hloekisa ka laser e tla fana ka tharollo ea ho hloekisa e tala le e se nang tšilafalo bakeng sa ho thibela ho bola ha libaka tsa likepe.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。

Nako ea poso: Jan-16-2024