Melao-motheo ea ho Welding Laser

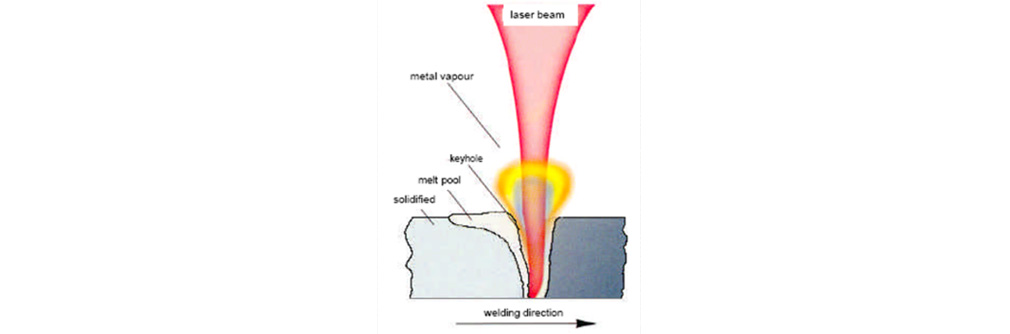

Ho chesoa ka lasere sebelisa litšobotsi tse ntle tsa tataiso le matla a phahameng a lebone la laser ho sebetsa.Ka tsamaiso ea optical, lebone la laser le tsepamisitsoe sebakeng se senyenyane haholo, ho theha mohloli oa mocheso o tsitsitseng haholo ka nako e khutšoanyane haholo.Ts'ebetso ena e qhibilihisa thepa sebakeng sa welding, e etsa sebaka se tiileng sa weld le seam.

·Laser welding ka kakaretso e arotsoe ka conduction welding le welding e tebileng ea ho kenella.

·Matla a matla a laser a 105~106w/cm2e fella ka ho tjheseletsa ha laser conduction.

·Matla a matla a laser a 105~106w/cm2e fella ka ho tjheseletsa ha laser deep penetration.

Litšobotsi tsa ho Welding Laser

Ha ho bapisoa le mekhoa e meng ea welding, laser welding e na le litšobotsi tse latelang:

·Matla a tsepamisitsoeng, ts'ebetso e phahameng ea welding, ts'ebetso e nepahetseng ea ts'ebetso e phahameng, le tekanyo e kholo ea botebo ho isa ho bophara ba seam ea weld.

·Kenyelletso e tlase ea mocheso, sebaka se senyenyane se anngoeng ke mocheso, khatello e fokolang ea masala, le deformation e tlase ea sesebelisoa.

·Li-welding tse se nang khokahanyo, phetisetso ea fiber optic, phihlello e ntle, le boemo bo holimo ba boits'oaro.

·Moralo o kopanetsoeng o feto-fetohang, o boloka lisebelisoa tse tala.

·Matla a ho tjheseletsa a ka laolwa ka nepo, a netefatsa diphetho tse tsitsitseng tsa welding le ponahalo e ntle ya welding.

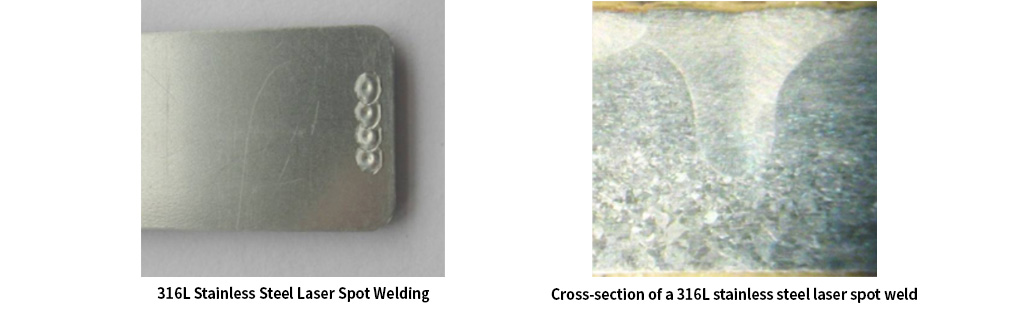

Welding of Steel le Alloys ea eona

·Litšepe tse sa hloekang li ka fumana litholoana tse ntle tsa welding ho sebelisa leqhubu le tloaelehileng la lisekoere.

·Ha u rala meaho e cheselitsoeng, leka ho boloka lintlha tsa weld li le hole le lintho tse seng tsa tšepe ka hohle kamoo ho ka khonehang.

·Ho fihlela litlhoko tsa matla le ponahalo, ho bohlokoa ho boloka sebaka se lekaneng sa welding le botenya ba workpiece.

·Nakong ea welding, ho bohlokoa ho netefatsa bohloeki ba mosebetsi le ho omella ha tikoloho.

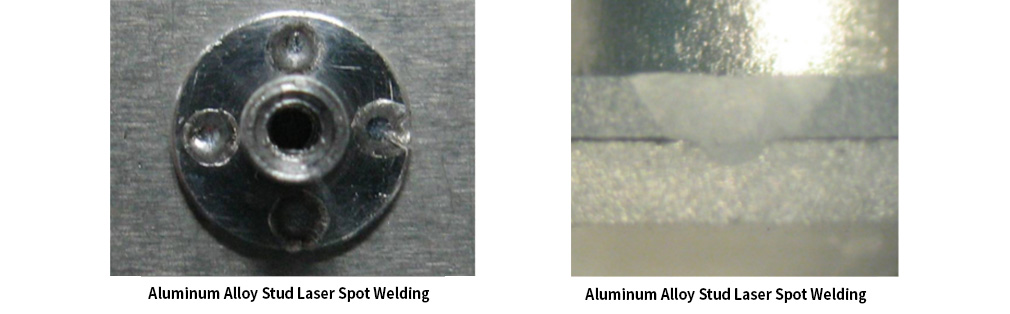

Welding ea Aluminium le Alloys ea eona

·Lisebelisoa tsa motsoako oa aluminium li na le ponahalo e phahameng;ka hona, ho hlokahala matla a phahameng a laser tlhōrō nakong ea ho tjheseletsa.

·Mapetsong a atisa ho etsahala nakong ea ho tjheseletsa ha pulse spot, ho ama matla a ho tjheseletsa.

·Sebopeho sa thepa se atisa ho arohana, se lebisang ho splattering.Ho eletsoa ho khetha lisebelisoa tse tala tsa boleng bo holimo.

·Ka kakaretso, ho sebelisa boholo bo boholo ba letheba le bophara bo bolelele ba pulse ho ka fihlela litholoana tse ntle tsa welding.

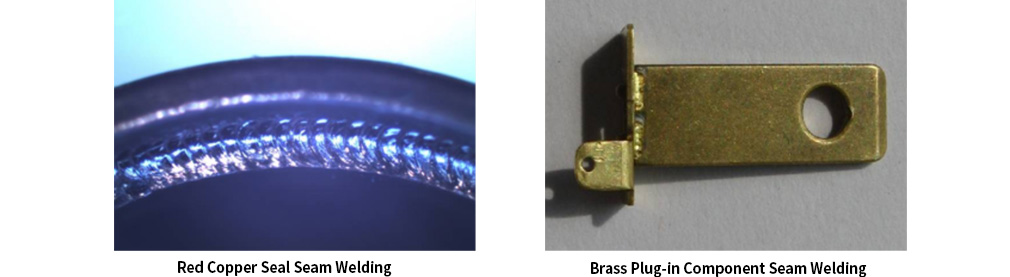

Welding of Copper le Alloys ea eona

·Lisebelisoa tsa koporo li na le ponahalo e holimo ha li bapisoa le lialloys tsa aluminium, tse hlokang matla a phahameng a laser a phahameng bakeng sa ho cheselletsa.Hlooho ea laser e hloka ho sekamisoa ka lehlakoreng le itseng.

·Bakeng sa li-alloys tse itseng tsa koporo, tse kang koporo le borone, bothata ba ho tjheseletsa bo eketseha ka lebaka la tšusumetso ea likarolo tsa alloy.Tlhokomeliso e lokela ho lefshoa ho khethoa ha mekhahlelo ea ts'ebetso ea welding.

Metal Welding e sa tšoaneng

·Na ho ka etsoa tharollo e tiileng.

·Na ho na le phapang e kholo ho electronegativity pakeng tsa litšepe tse sa tšoaneng.

·Lintlha tse ling tse susumetsang.

Hore na litšepe tse sa tšoaneng li ka etsa manonyeletso a boleng bo holimo haholo-holo ho ipapisitse le thepa ea 'mele, thepa ea lik'hemik'hale, sebopeho sa lik'hemik'hale, le mehato ea ts'ebetso ea litšepe tse lokelang ho chesetsoa.Hangata sena se nahanoa ka lintlha tse latelang:

·Hore na tharollo e tiileng e ka etsoa ho itšetlehile ka hore na litšepe tse sa tšoaneng li ka qhibiliha ka bobeli boemong ba mokelikeli le bo tiileng.Ke feela ha ba ka qhalana ka nako e sa lekanyetsoang, motsoako o matla le o tiileng oa weld o ka thehoa.Ka kakaretso, ho qhibiliha ha bohlokoa, kapa esita le ho qhibiliha ho sa lekanyetsoang, ho ka finyelloa feela ha phapang ea radius ea athomo pakeng tsa litšepe tse peli e le ka tlase ho hoo e ka bang 14% ho isa ho 15%.

·Hore na ho na le phapang e kholo ea ho sebelisana ha motlakase pakeng tsa litšepe tse sa tšoaneng le hona ho bohlokoa.Phapang e kholoanyane, e matlafatsa kamano ea bona ea lik'hemik'hale, e atisang ho lebisa ho thehoa ha metsoako ho e-na le tharollo e tiileng.Ka lebaka leo, ho qhibiliha ha tharollo e tiileng e entsoeng ho fokotseha, 'me matla a motsoako oa weld a boetse a fokotseha.

·Ho feta moo, ho chesetsoa ha litšepe tse sa tšoaneng ho angoa haholo ke thepa e kang lintlha tse qhibilihang, li-coefficients tsa katoloso ea mocheso, li-conductivity tsa mocheso, mocheso o itseng, oxidizability, le reflectivity ea thepa e amehang.Phapang e kholoanyane linthong tsena tsa 'mele, ho ba thata le ho feta ho cheselletsa, 'me matla a lenonyeletso le hlahang a atisa ho ba matla.

·Hangata, laser welding ea lisebelisoa tsa tšepe tse sa tšoaneng tse kang tšepe e nang le koporo, aluminium, le nickel, hammoho le koporo e nang le nickel, e bonts'a ts'ebetso e ntle ea weldability, e lebisang ho boleng bo khotsofatsang ba ho cheselletsa.

Laser welding e fumana lits'ebetso tse pharalletseng makaleng a fapaneng, ho kenyeletsoa empa e sa felle libakeng tse latelang:

1: Metal Welding e sa Tšoaneng

Laser welding e sebelisoa haholo indastering ea tlhahiso e kang ea likoloi, sefofane, lisebelisoa tsa elektroniki le boenjiniere ba mechini.E sebelisoa bakeng sa likarolo tsa ho tjheseletsa le ho kopanya meaho, ho ntlafatsa katleho ea tlhahiso le boleng ba sehlahisoa.

2: Lisebelisoa tsa Bongaka

Ha ho etsoa lisebelisoa tsa bongaka, welding ea laser e sebelisoa bakeng sa ho hokahanya le ho kopanya likaroloana tse nyane, tse nepahetseng, ho netefatsa lihlahisoa tsa boleng bo holimo ha ho ntse ho qoba tšusumetso e feteletseng ea mocheso thepa.

3: Tsa elektroniki

Ka lebaka la ho nepahala ha eona ho phahameng le ho kenya mocheso o tlase, welding ea laser e sebelisoa haholo ha ho etsoa lisebelisoa tsa elektroniki, ho kenyeletsoa welding board board le microelectronic components.

4: Sepakapaka

Ho tjheseletsa ka laser ho sebediswa lekaleng la difofane bakeng sa ho etsa difofane le dikarolo tsa sepakapaka, ho kgontsha moralo o bobebe le dikgokelo tse matla haholo.

5: Lekala la Matla

Indastering ea matla, laser welding e sebelisoa bakeng sa ho etsa liphanele tsa letsatsi, lisebelisoa tsa matla a nyutlelie, le likarolo tse ling tse amanang le tlhahiso ea matla.

6: Mabenyane le Ho Etsa Lioache

Ka lebaka la ho ikamahanya le maemo ho meaho e metle le e rarahaneng, welding ea laser e atisa ho sebelisoa ha ho etsoa mabenyane le lioache bakeng sa ho hokahanya le ho lokisa likaroloana tse pshatlehang.

7: Indasteri ea Likoloi

Tlhahisong ea likoloi, laser welding e sebelisoa bakeng sa ho hokahanya likarolo tsa koloi, ho ntlafatsa ts'ebetso ea ho cheselletsa, le ho ntlafatsa boleng ba sehlahisoa.

Ka kakaretso, ho nepahala ho phahameng, lebelo, le ho feto-fetoha ha laser welding ho etsa hore e sebetse haholo masimong a tlhahiso le a tlhahiso.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。

Nako ea poso: Jan-17-2024