Ho Seha Khalase ea Laser

Khalase e sebelisoa haholo homasimo, joalo kakoloi, photovoltaic,skrineng, le lisebelisoa tsa lapengs ka lebaka la eonamelemo e kenyeletsangsebopeho se fapaneng,hodimophetisovity, le litšenyehelo tse laoloang.Ho na le tlhokahalo e ntseng e eketseha ea ts'ebetso ea likhalase ka nepo e phahameng, lebelo le potlakileng, le maemo a fetohang haholoanyane (joalo ka ts'ebetso ea curve le ts'ebetso e sa tloaelehang ea paterone) masimong ana.Leha ho le joalo, ho senyeha ha khalase ho boetse ho baka mathata a mangata a ho sebetsa, joalo ka mapheo, li-chips,lemathoko a sa lekana.Ke enaJoangthelaser e ka khonatshebetsolisebelisoa tsa khalase le ho thusa ho sebetsa ha likhalase ho ntlafalatlhahiso.

Ho Seha Khalase ea Laser

Har'a mekhoa e tloaelehileng ea ho itšeha likhalase, e tloaelehileng haholo ke ho itšeha ka mochini, ho seha malakabe,leho seha ha metsi.Melemo le melemo ea mekhoa ena e meraro ea setso ea ho itšeha likhalaseke tse latelang.

Ho Seha ka Mechini

Melemo

1. Theko e tlaase le ts'ebetso e bonolo

2. Smooth seha Mathata

Mefokolo

1.Ho hlahisa li-chips le li-micro-cracks tse bonolo, tse bakang matla a fokotsehileng a sehiloeng le ho sila ha CNC ho hlokahala.

2.Litšenyehelo tse phahameng tsa ho itšeha: sesebelisoa se bonolo ho se apara le ho nkeloa sebaka kamehla ho hlokahalang

3.Tlhahiso e tlaase: ke mela e otlolohileng feela ea ho itšeha ho khoneha le ho thata ho khaola mekhoa e bōpehileng

Ho Cheka Lelakabe

Melemo

1. Theko e tlaase le ts'ebetso e bonolo

Mefokolo

1.High thermal deformation, e thibelang ho sebetsa ka mokhoa o nepahetseng

2.Lebelo le tlaase le katleho e tlaase, e thibelang tlhahiso ea bongata

3.Ho chesa mafura, e seng botsoalle ba tikoloho

Waterjet Cutting

Melemo

1.CNC ho itšeha ea mekhoa e sa tšoaneng e rarahaneng

2.Ho itšeha ho batang: ha ho na deformation ea mocheso kapa liphello tsa mocheso

3.Smooth ho itšeha: ho cheka ka nepo, ho seha le ho bopa ho felile 'me ha ho hlokahale hore ho etsoe tšebetso ea bobeli.

Mefokolo

1.Litšenyehelo tse phahameng: tšebeliso ea metsi a mangata le lehlabathe le litšenyehelo tse phahameng tsa tlhokomelo

2.Tšilafalo e phahameng le lerata ho tikoloho ea tlhahiso

3.Matla a matla a maholo: ha a tšoanelehe bakeng sa ho sebetsana le lipampiri tse tšesaane

Ho itšeha ka likhalase tsa setso ho na le mathata a mangata, joalo ka lebelo le liehang, litšenyehelo tse phahameng, ts'ebetso e fokolang, boemo bo thata, le tlhahiso e bonolo ea likhalase tsa likhalase, mapetsong le mapheo a sa lekaneng.Ho phaella moo, ho hlokahala mehato e fapa-fapaneng ea ka mor'a ts'ebetso (e kang ho hlatsoa, ho sila le ho bentša) ho fokotsa mathata ana, e leng ho eketsang nako le litšenyehelo tse eketsehileng tsa tlhahiso.

Ka nts'etsopele ea theknoloji ea laser, ho seha likhalase tsa laser, ts'ebetso e sa amaneng le batho, e ntse e tsoela pele.Taeo ea eona ea ts'ebetso ke ho tsepamisa laser karolong e bohareng ea khalase le ho theha sebaka se phatlohileng sa longitudinal le lateral ka fusion ea mocheso, e le ho fetola tlamo ea limolek'hule tsa khalase.Ka tsela ena, matla a eketsehileng a tšusumetso ka khalaseng a ka qojoa ntle le tšilafalo ea lerōle le ho itšeha ha taper.Ho feta moo, likarolo tse sa tsitsang li ka laoloa ka hare ho 10um.Ho itšeha ka khalase ea laser ho bonolo ho sebetsa le ho boloka tikoloho 'me ho qoba mathata a mangata a ho itšeha ka khalase ea setso.

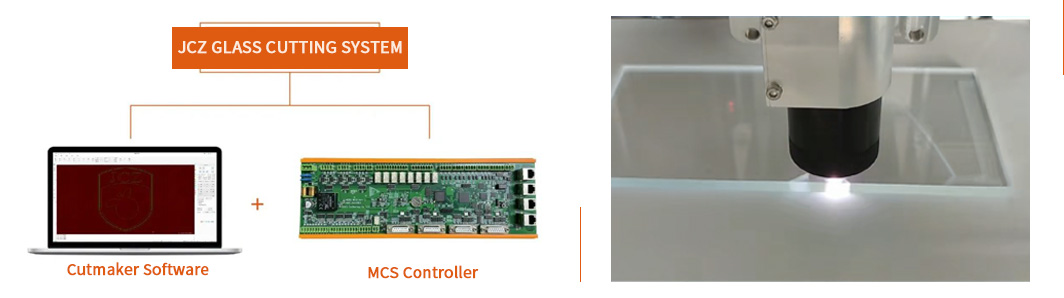

BJJCZ e thakhola JCZ Glass Cutting System, e khutsufalitsoeng e le P2000, bakeng sa ho seha likhalase tsa laser.Mokhoa ona o kenyelletsa ts'ebetso ea PSO (ho nepahala ha sebaka sa arc ho fihla ho ± 0.2um ka lebelo la 500mm / s), e ka khaolang khalase ka lebelo le phahameng le ho nepahala ho phahameng.Ka ho kopanya melemo ena le karohano ea ka mor'a ts'ebetso, lisebelisoa tsa boleng bo holimo li ka finyelloa.Sistimi ena e na le melemo ea ho nepahala ho phahameng, ha ho na li-micro-cracks, ha ho na ho robeha, ha ho na li-chips, ho hanyetsa moeli o phahameng oa ho robeha, 'me ha ho na tlhoko ea ts'ebetso ea bobeli joalo ka rinsing, grinding le polishing, tseo kaofela li ntlafatsang haholo tlhahiso le katleho ha li ntse li sebetsa. ho fokotsa litšenyehelo.

Ho sebetsa Setšoantšo sa Laser Glass Cutting

JCZ Glass Cutting System e ka sebelisoa ho sebetsana le likhalase tse tšesaane haholo le libopeho le lipaterone tse rarahaneng.E sebelisoa hangata ho mehala ea cellular, lisebelisoa tsa elektroniki tsa bareki, lihlahisoa tsa elektroniki tsa 3C, likhalase tse sireletsang likoloi, li-skrini tsa lapeng tse bohlale, lisebelisoa tsa khalase, lilense le likarolo tse ling.

Ho Cheka Khalase ea Laser

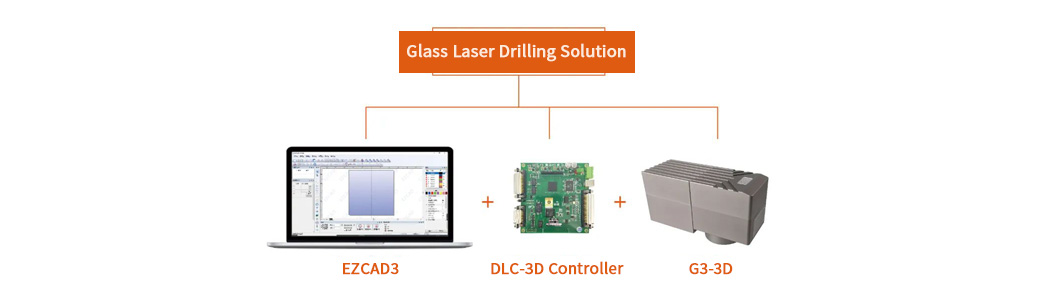

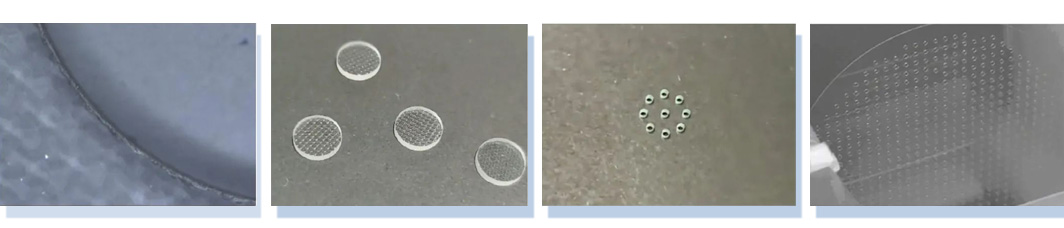

Li-laser li ka sebelisoa eseng feela ka ho itšeha ka khalase, empa hape le ts'ebetsong ea likoti tse nang le li-apertures tse fapaneng holim'a khalase, hammoho le likoti tse nyenyane.

Tharollo ea ho cheka likhalase tsa JCZ laser e ka sebelisoa ho sebetsana le lisebelisoa tse fapaneng tsa khalase, joalo ka khalase ea quartz, khalase e kobehileng, khalase e tšesaane haholo ntlha ka ntlha, mola ka mola, le lera ka lera le nang le taolo e phahameng.E na le melemo e mengata, ho kenyelletsa le ho feto-fetoha ha maemo ho phahameng, lebelo le phahameng, ho nepahala ho phahameng, botsitso bo phahameng, le ts'ebetso ea lipaterone tse fapaneng, joalo ka likoti tse lisekoere, likoti tse chitja, le likoti tsa listello.

Tharollo ea ho cheka likhalase tsa JCZ laser e ka sebelisoa ho khalase ea photovoltaic, li-skrini, likhalase tsa bongaka, lisebelisoa tsa motlakase tsa bareki, le lisebelisoa tsa elektroniki tsa 3C.

Ka nts'etsopele e tsoelang pele ea tlhahiso ea likhalase le theknoloji ea ho lokisa likhalase le ho hlaha ha lasers, mekhoa e mecha ea ho lokisa likhalase e fumaneha matsatsing ana.Tlas'a taolo e nepahetseng ea sistimi ea taolo ea laser, ts'ebetso e nepahetseng haholoanyane le e sebetsang e fetoha khetho e ncha.

Nako ea poso: May-06-2022