Imigaqo yeLaser Welding

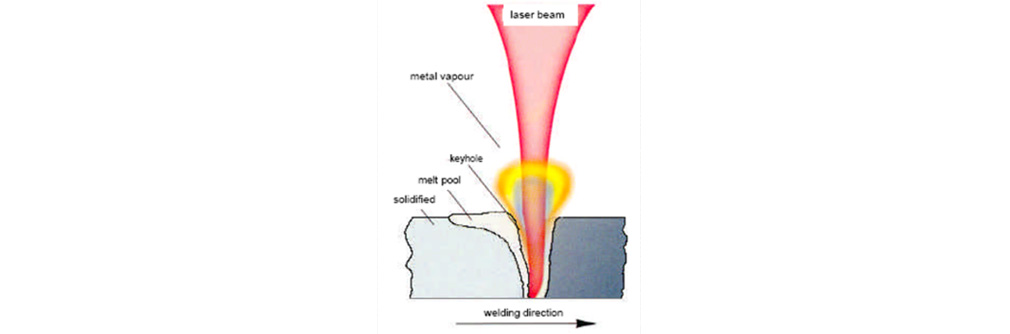

Ukuwelda kweLaserisebenzisa umkhombandlela obalaseleyo kunye neempawu zoxinaniso lwamandla aphezulu omqa welaser ukusebenza.Ngenkqubo ye-optical, i-laser beam igxininise kwindawo encinci kakhulu, idala umthombo wokushisa ogxininisiweyo kakhulu kwixesha elifutshane kakhulu.Le nkqubo iyayinyibilikisa izinto kwindawo ye-welding, yenza indawo eqinile ye-weld kunye nomthungo.

·Ukuwelda kweLaser ngokuqhelekileyo kwahlulwe kwi-welding conduction kunye ne-welding yokungena enzulu.

·Ukuxinana kwamandla e-laser ye-105~106w/cm2iziphumo kwi-laser conduction welding.

·Ukuxinana kwamandla e-laser ye-105~106w/cm2iziphumo kwi welding laser deep penetration.

Iimpawu zeLaser Welding

Xa kuthelekiswa nezinye iindlela zokuwelda, ukuwelda ngelaser kunezi mpawu zilandelayo:

·Amandla agxilileyo, ukusebenza kakuhle kwe-welding, ukuchaneka okuphezulu kokusebenza, kunye nomlinganiselo omkhulu wobunzulu ukuya kububanzi bomthungo we-weld.

·Ukufakwa kobushushu obuphantsi, indawo encinci echaphazelekileyo kubushushu, uxinzelelo oluncinci lokushiyeka, kunye nokuguqulwa okuphantsi kwendawo yokusebenza.

·I-welding engadibanisiyo, i-fiber optic transmission, ukufikeleleka kakuhle, kunye nenqanaba eliphezulu lokuzisebenzela.

·Uyilo oludibeneyo oluguquguqukayo, ukugcina izinto eziluhlaza.

·Amandla e-welding anokulawulwa ngokuchanekileyo, ukuqinisekisa iziphumo ezizinzileyo ze-welding kunye nokubonakala kakuhle kwe-welding.

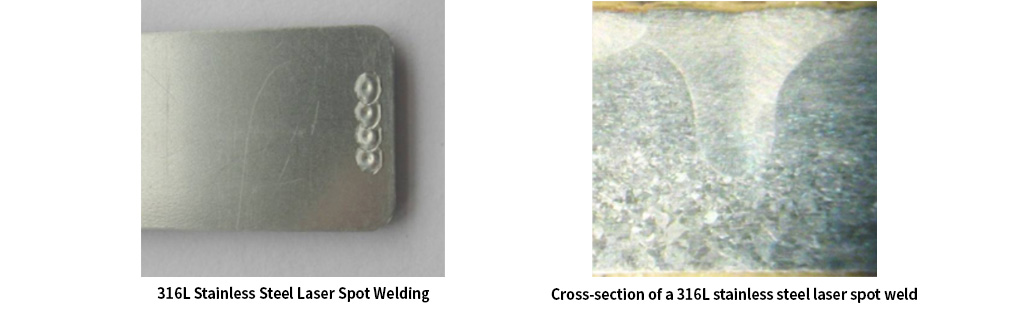

Welding of Steel kunye nealloys zayo

·Insimbi engenasici inokufezekisa iziphumo ezilungileyo ze-welding usebenzisa i-standard square wave.

·Xa uyila izakhiwo ezidityanisiweyo, zama ukugcina amanqaku e-weld kude nezinto ezingezizo ezentsimbi kangangoko kunokwenzeka.

·Ukuhlangabezana neemfuno zamandla kunye nenkangeleko, kuyacetyiswa ukuba ugcine indawo eyaneleyo ye-welding kunye nobukhulu be-workpiece.

·Ngexesha le-welding, kubalulekile ukuqinisekisa ukucoceka kwendawo yokusebenza kunye nokoma kokusingqongileyo.

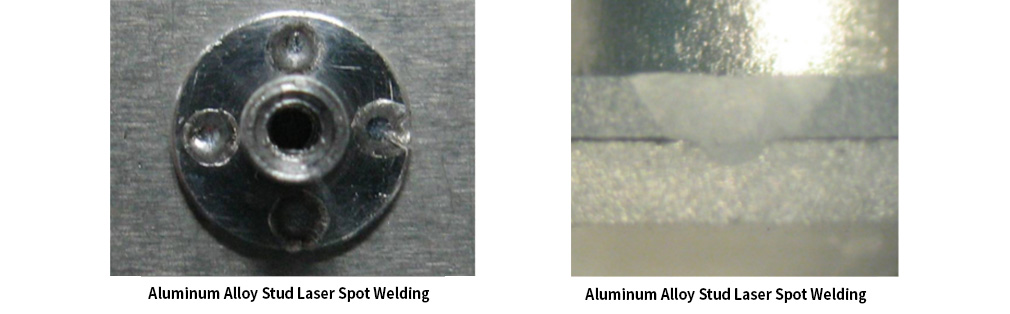

Ukuwelda kweAluminiyam kunye neeAlloys zayo

·Izinto ze-aluminium alloy zine-reflection ephezulu;ke ngoko, amandla aphezulu encopho ye-laser ayadingeka ngexesha le-welding.

·Iintanda zivame ukwenzeka ngexesha le-pulse spot welding, echaphazela amandla e-welding.

·Ukubunjwa kwezinto eziphathekayo kukulungele ukuhlukana, okukhokelela ekutshizeni.Kuyacetyiswa ukuba ukhethe izixhobo ezikumgangatho ophezulu.

·Ngokubanzi, ukusebenzisa ubungakanani bendawo enkulu kunye nobubanzi be-pulse emide kunokufikelela kwiziphumo ezingcono zokuwelda.

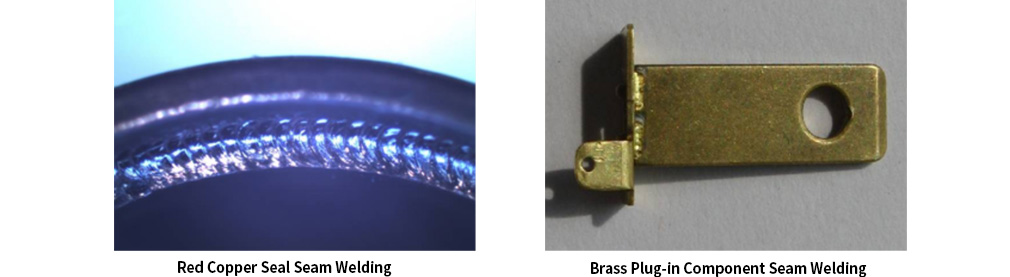

Welding of Copper kunye neAlloys zayo

·Izixhobo zobhedu zinokubonakala okuphezulu xa kuthelekiswa ne-alloys ye-aluminium, efuna amandla aphezulu e-laser yokuwelda.Intloko ye-laser kufuneka ithotywe kwi-angle ethile.

·Kwii-alloys ezithile zobhedu, ezifana nobhedu kunye nobhedu, ubunzima be-welding buyanda ngenxa yefuthe lezinto ze-alloy.Ingqalelo kufuneka ihlawulwe ekukhethweni kweeparamitha zenkqubo ye-welding.

Ukuwelda kweMetal okungafaniyo

·Ingaba isisombululo esiluqilima singenziwa.

·Ngaba kukho umahluko omkhulu kwi-electronegativity phakathi kweentsimbi ezingafaniyo.

·Ezinye izinto ezinempembelelo.

Nokuba iintsimbi ezingafaniyo zinokubumba iindawo zokuwelda ezikumgangatho ophezulu ikakhulu kuxhomekeke kwiipropati zomzimba, iipropathi zekhemikhali, ukwakheka kweekhemikhali, kunye nemilinganiselo yenkqubo yesinyithi ekufuneka idityaniswe.Oku kujongwa ngokwesiqhelo kule miba ilandelayo:

·Ukuba isisombululo esiluqilima sinokubunjwa kuxhomekeke ekubeni iintsimbi ezingafaniyo zinokunyibilika ngokufanayo kulwelo nakwilizwe eliqinileyo.Kuphela xa zinokunyibilika komnye nomnye ngokungenasiphelo, i-weld joint weld inokwakheka.Ngokubanzi, ukunyibilika okubalulekileyo, okanye ukunyibilika okungenamkhawulo, kufumaneka kuphela xa umahluko weradiyasi yeathom phakathi kwezi zinyithi zimbini ungaphantsi kwe-14% ukuya kwi-15%.

·Nokuba kukho umahluko omkhulu kwi-electronegativity phakathi kweentsimbi ezahlukeneyo nako kubalulekile.Okukhona umahluko omkhulu, kokukhona womelele ukunxulumana kwabo kweekhemikhali, okukholisa ukukhokelela ekwakhiweni kweekhompawundi kunezisombululo eziqinileyo.Ngenxa yoko, i-solubility yesisombululo esiqinileyo esakhiweyo siyancitshiswa, kwaye amandla okudibanisa i-weld nawo aphantsi.

·Ukongeza, ukuwelda kweentsimbi ezingafaniyo kuchaphazeleka kakhulu ziipropathi ezinje ngeendawo zokunyibilika, i-coefficients yokwandiswa kwe-thermal, i-thermal conductivities, ukushisa okuthe ngqo, i-oxidizability, kunye nokubonakaliswa kwezinto ezibandakanyekayo.Okukhona umahluko omkhulu kwezi zakhiwo zomzimba, kokukhona kuba ngumceli mngeni ukuwelda, kwaye kokukhona ubuthathaka amandla esiphumo se-weld joint sithanda ukuba.

·Ngokuqhelekileyo, i-laser welding yezixhobo zetsimbi ezahlukeneyo ezifana nentsimbi enobhedu, i-aluminiyam, kunye ne-nickel, kunye nobhedu olune-nickel, ibonisa ukuwelda okulungileyo, okukhokelela kumgangatho owanelisayo we-welding.

I-Laser welding ifumana izicelo ezibanzi kuwo wonke amacandelo ahlukeneyo, kubandakanywa kodwa kungaphelelanga kwezi ndawo zilandelayo:

1: Ukuwelda kweMetal okungafaniyo

I-laser welding isetyenziswa kakhulu kumashishini okuvelisa anjengeemoto, i-aerospace, i-electronics, kunye nobunjineli boomatshini.Isetyenziselwa amacandelo e-welding kunye nezakhiwo zokudibanisa, ukuphucula ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso.

2: Izixhobo zonyango

Ekwenziweni kwezixhobo zonyango, i-laser welding isetyenziselwa ukudibanisa kunye nokudibanisa izinto ezincinci, ezichanekileyo, ukuqinisekisa iimveliso ezikumgangatho ophezulu ngelixa uthintela ukushisa okugqithisileyo kwizinto eziphathekayo.

3: Ezombane

Ngenxa yokuchaneka kwayo okuphezulu kunye negalelo eliphantsi lobushushu, i-laser welding isetyenziswa ngokubanzi ekwenzeni izixhobo zombane, kubandakanywa ukuwelda kwebhodi yesekethe kunye namacandelo e-microelectronic.

4: I-Aerospace

I-laser welding isetyenziswa kwicandelo le-aerospace yokuvelisa iinqwelomoya kunye nezixhobo ze-aerospace, okwenza uyilo olulula kunye noqhagamshelwano oluphezulu lwamandla.

5: Icandelo lezaMandla

Kwishishini lamandla, i-laser welding isetyenziselwa ukuvelisa iiphaneli zelanga, izixhobo zamandla enyukliya, kunye nezinye izinto ezinxulumene nokuveliswa kwamandla.

6: Ubucwebe kunye nokwenza iiwotshi

Ngenxa yokuguquguquka kwayo kwizinto ezintle kunye nezintsonkothileyo, i-laser welding ihlala isetyenziselwa ukwenziwa kwezacholo kunye neewotshi zokudibanisa kunye nokulungisa izinto ezibuthathaka.

7: Ushishino lweemoto

Kwimveliso yeemoto, i-laser welding isetyenziselwa ukudibanisa izinto zemoto, ukuphucula ukusebenza kakuhle kwe-welding, kunye nokuphucula umgangatho wemveliso.

Ngokubanzi, ukuchaneka okuphezulu, isantya, kunye nokuguquguquka kwe-laser welding kuyenza isebenze ngokubanzi kwimveliso kunye nemveliso.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。

Ixesha lokuposa: Jan-17-2024