Izimiso Laser Welding

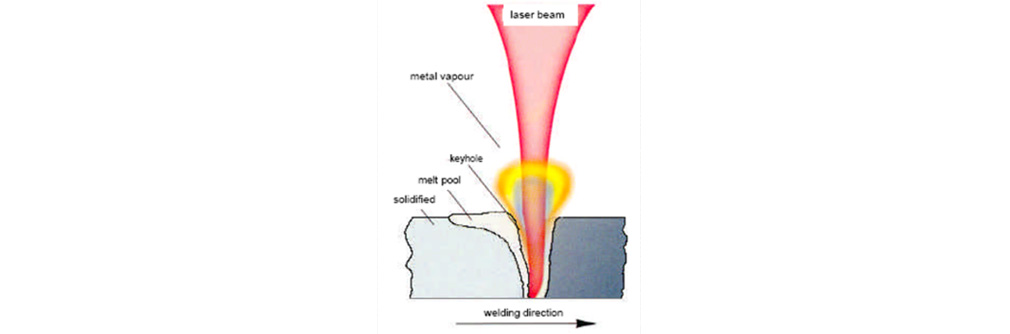

I-laser weldingisebenzisa izici ezinhle kakhulu zokuqondisa kanye nezici eziphezulu zokuminyana kwe-laser ukuze isebenze.Ngesistimu ye-optical, i-laser beam igxile endaweni encane kakhulu, idala umthombo wokushisa ogxile kakhulu esikhathini esifushane kakhulu.Le nqubo incibilikisa i-material endaweni yokushisela, yakhe indawo eqinile ye-weld kanye nomthungo.

·I-laser welding ngokuvamile ihlukaniswe nge-welding conduction kanye ne-deep penetration welding.

·Ukuminyana kwamandla we-laser okungu-105~106w/cm2umphumela we-laser conduction welding.

·Ukuminyana kwamandla we-laser okungu-105~106w/cm2umphumela we-laser deep penetration welding.

Izici ze-Laser Welding

Uma kuqhathaniswa nezinye izindlela zokushisela, i-laser welding inezici ezilandelayo:

·Amandla agxilile, ukusebenza kahle okuphezulu kokushisela, ukunemba okuphezulu kokucubungula, kanye nesilinganiso esikhulu sokujula kobubanzi bomthungo wokushisela.

·Okokufaka okuphansi kokushisa, indawo encane ethinteke ukushisa, ingcindezi encane eyinsalela, nokonakala okuphansi kwendawo yokusebenza.

·I-non-contact welding, i-fiber optic transmission, ukufinyeleleka okuhle, nezinga eliphezulu lokuzishintshanisa.

·Idizayini ehlangene eguquguqukayo, okonga izinto ezingavuthiwe.

·Amandla e-welding angalawulwa ngokunembile, aqinisekise imiphumela ezinzile ye-welding kanye nokubukeka okuhle kokushisela.

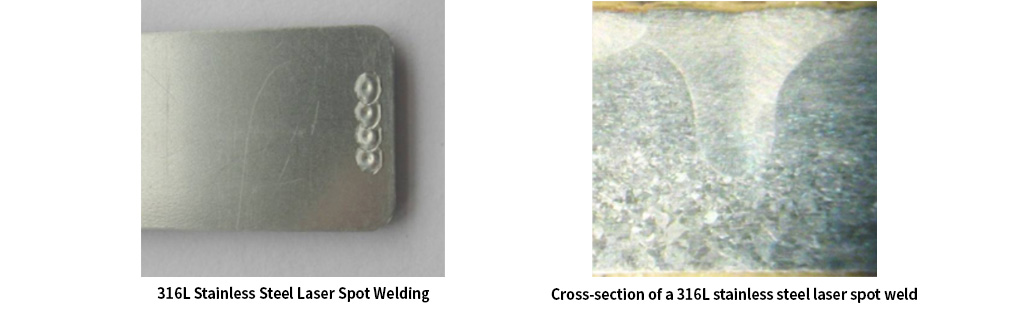

Welding of Steel kanye Alloys yayo

·Insimbi engagqwali ingafinyelela imiphumela emihle yokushisela isebenzisa igagasi lesikwele elijwayelekile.

·Lapho uklama izakhiwo ezishiselwe, zama ukugcina amaphuzu e-weld kude nezinto ezingezona ezensimbi ngangokunokwenzeka.

·Ukuze uhlangabezane nezidingo zamandla nokubukeka, kuhle ukugcina indawo eyanele yokushisela kanye nobukhulu be-workpiece.

·Ngesikhathi sokushisela, kubalulekile ukuqinisekisa ukuhlanzeka kwendawo yokusebenza kanye nokomisa kwemvelo.

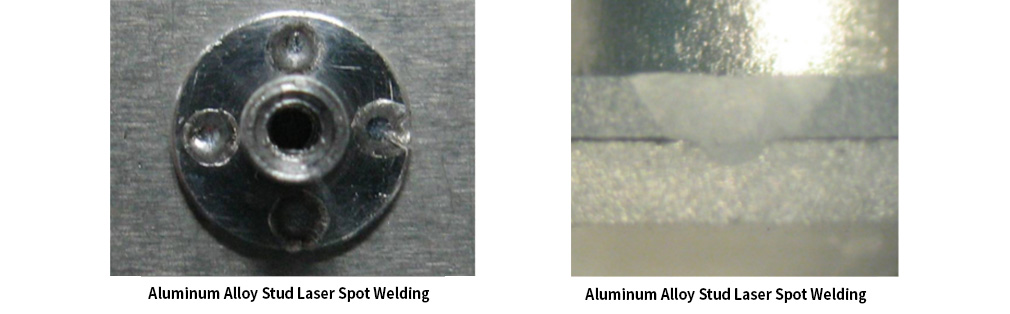

Ukushiselwa kwe-Aluminium nama-alloys ayo

·Izinto ze-aluminium alloy zinokubukeka okuphezulu;ngakho-ke, amandla aphezulu aphezulu we-laser ayadingeka ngesikhathi sokushisela.

·Imifantu ijwayele ukwenzeka ngesikhathi se-pulse spot welding, ithinta amandla okushisela.

·Ukwakheka kwezinto ezibonakalayo kujwayele ukuhlukaniswa, okuholela ekusakazeni.Kunconywa ukukhetha izinto ezingavuthiwe eziphezulu.

·Ngokuvamile, ukusebenzisa usayizi wendawo enkulu kanye nobubanzi be-pulse ende kungafinyelela imiphumela engcono yokushisela.

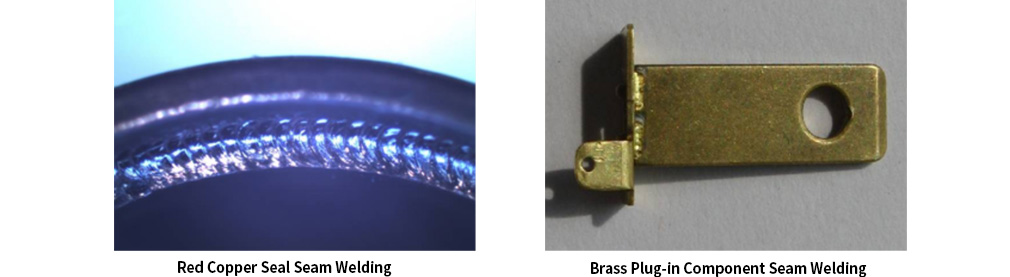

Welding of Copper kanye Alloys yayo

·Izinto zethusi zinokubonakala okuphezulu uma kuqhathaniswa nama-alloys e-aluminium, adinga amandla aphezulu e-laser aphakeme kakhulu wokushisela.Ikhanda le-laser lidinga ukutshekiswa nge-engeli ethile.

·Kuma-alloys athile ethusi, njengethusi nethusi, ubunzima be-welding buyanda ngenxa yethonya lezakhi ze-alloy.Ukunakwa kufanele kukhokhwe ekukhethweni kwemingcele yenqubo yokushisela.

I-Metal Welding Ehlukile

·Ingabe isixazululo esiqinile singakhiwa.

·Ingabe ukhona umehluko omkhulu ku-electronegativity phakathi kwezinsimbi ezingafani.

·Ezinye izici ezinomthelela.

Ukuthi izinsimbi ezingafani zingakha amajoyinti okushisela ekhwalithi ephezulu ikakhulukazi kuncike ezintweni ezibonakalayo, izakhiwo zamakhemikhali, ukwakheka kwamakhemikhali, kanye nezinqubo zezinqubo zezinsimbi ezizoshiselwa.Lokhu ngokuvamile kucatshangelwa kusukela ezicini ezilandelayo:

·Ukuthi isixazululo esiqinile singakheka yini kuncike ekutheni izinsimbi ezingafani zingancibilika ngokulinganayo endaweni ewuketshezi noma eqinile.Kuphela lapho zingancibilika komunye nomunye unomphela, inhlanganisela ye-weld eqinile futhi eqinile ingakhiwa.Ngokuvamile, ukuncibilika okubalulekile, noma ukunyibilika okungenamkhawulo, kufinyeleleka kuphela uma umehluko werediyasi ye-athomu phakathi kwezinsimbi ezimbili ungaphansi cishe kuka-14% kuya ku-15%.

·Ukuthi ngabe kunomehluko omkhulu ku-electronegativity phakathi kwezinsimbi ezingafani nakho kubalulekile.Uma umehluko omkhulu, ukuqina kwawo kwamakhemikhali okuhambisana, okuvame ukuholela ekwakhekeni kwezinhlanganisela kunezixazululo eziqinile.Ngenxa yalokho, ukuncibilika kwesisombululo esiqinile esakhiwe kuyancishiswa, futhi amandla okuhlangana kwe-weld nawo aphansi.

·Ukwengeza, ukushiselwa kwezinsimbi ezingafani kuthinteka kakhulu yizakhiwo ezinjengamaphoyinti ancibilikayo, ama-coefficients of thermal conductivity, ama-thermal conductivities, ukushisa okuthile, i-oxidizability, kanye nokubonakala kwezinto ezihilelekile.Uma umehluko omkhulu kulezi zici ezingokomzimba, kuba yinselele kakhulu ukushisela, futhi aba buthaka amandla ejoyinti le-weld eliwumphumela livame ukuba namandla.

·Ngokuvamile, ukushisela nge-laser kwezinto zensimbi ezingafani njengensimbi yethusi, i-aluminium, ne-nickel, kanye nethusi eline-nickel, kukhombisa ukushisela okuhle, okuholela kwikhwalithi yokushisela egculisayo.

I-laser welding ithola ukusetshenziswa okubanzi emikhakheni ehlukahlukene, kufaka phakathi kodwa kungagcini kulezi zindawo ezilandelayo:

1: I-Metal Welding Engafani

I-laser welding isetshenziswa kakhulu ezimbonini zokukhiqiza ezifana nezimoto, i-aerospace, electronics, kanye nobunjiniyela bemishini.Isetshenziselwa izingxenye zokushisela kanye nokuhlanganisa izakhiwo, ukuthuthukisa ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo.

2: Amadivayisi Ezokwelapha

Ekwenziweni kwemishini yezokwelapha, i-laser welding isetshenziselwa ukuxhuma nokuhlanganisa izingxenye ezincane, ezinembayo, ukuqinisekisa imikhiqizo yekhwalithi ephezulu kuyilapho kugwenywa umthelela omkhulu wokushisa ezintweni.

3: Ezogesi

Ngenxa yokunemba kwayo okuphezulu nokokufaka kokushisa okuphansi, i-laser welding isetshenziswa kabanzi ekukhiqizeni izinto zikagesi, okuhlanganisa ukushisela ibhodi lesifunda kanye nezingxenye ze-microelectronic.

4: Umkhathi

I-laser welding isetshenziswa emkhakheni we-aerospace ekwenzeni izindiza nezingxenye ze-aerospace, okuvumela ukuklama okungasindi kanye nokuxhumana okunamandla aphezulu.

5: Umkhakha wezamandla

Embonini yamandla, i-laser welding isetshenziselwa ukukhiqiza amaphaneli elanga, okokusebenza kwamandla enuzi, nezinye izakhi ezihlobene nokukhiqizwa kwamandla.

6: Ubucwebe kanye nokwenza amawashi

Uma kubhekwa ukuguquguquka kwayo kwezakhiwo ezinhle neziyinkimbinkimbi, i-laser welding ivame ukusetshenziswa ekukhiqizeni ubucwebe namawashi okuxhuma nokulungisa izingxenye ezithambile.

7: Imboni Yezimoto

Emkhiqizweni wezimoto, i-laser welding isetshenziselwa ukuxhuma izingxenye zezimoto, ukuthuthukisa ukusebenza kahle kokushisela, kanye nokuthuthukisa ikhwalithi yomkhiqizo.

Sekukonke, ukunemba okuphezulu, isivinini, kanye nokuguquguquka kwe-laser welding kuyenza isebenze kabanzi emikhakheni yokukhiqiza neyokukhiqiza.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。

Isikhathi sokuthumela: Jan-17-2024