Ka'idodin Laser Welding

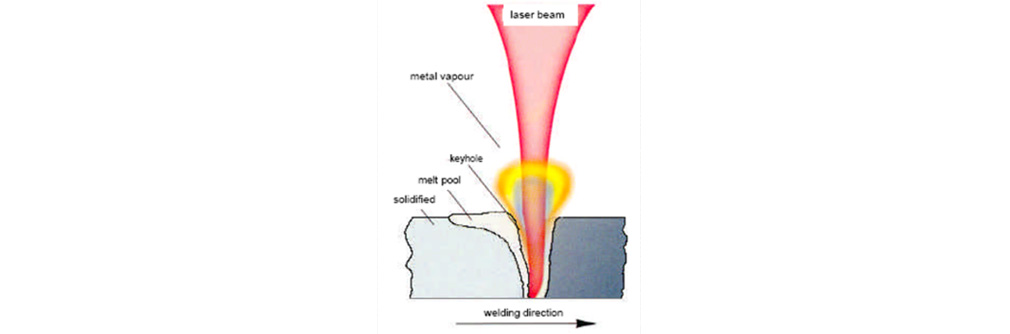

Laser waldayana amfani da ingantattun kwatance da halayen ƙarfin ƙarfin ƙarfi na katako don yin aiki.Ta hanyar tsarin gani, hasken laser yana mai da hankali kan ƙaramin yanki, yana ƙirƙirar tushen zafi sosai a cikin ɗan gajeren lokaci.Wannan tsari yana narkar da kayan a wurin walda, yana samar da tabo mai ƙarfi mai ƙarfi da kabu.

·Waldawar Laser gabaɗaya ya kasu kashi-kashi cikin walƙiyar conduction da walƙiya mai zurfi.

·Girman ƙarfin Laser na 105~106w/cm2yana haifar da walƙiya na walƙiya.

·Girman ƙarfin Laser na 105~106w/cm2sakamakon Laser zurfin shigar waldi.

Halayen Welding Laser

Idan aka kwatanta da sauran hanyoyin walda, waldar laser tana da halaye masu zuwa:

·Mayar da hankali makamashi, high waldi ingancin, high aiki madaidaicin, da kuma babban zurfin-to-nisa rabo na weld dinki.

·Ƙunƙarar shigarwar zafi, ƙaramin yankin da zafi ya shafa, ƙarancin saura damuwa, da ƙarancin nakasu na kayan aikin.

·Walda mara lamba, watsa fiber optic, samun dama mai kyau, da babban matakin sarrafa kansa.

·Tsarin haɗin gwiwa mai sassauƙa, adana albarkatun ƙasa.

·Ana iya sarrafa makamashin walda daidai gwargwado, yana tabbatar da barga sakamakon walda da kyakkyawan bayyanar walda.

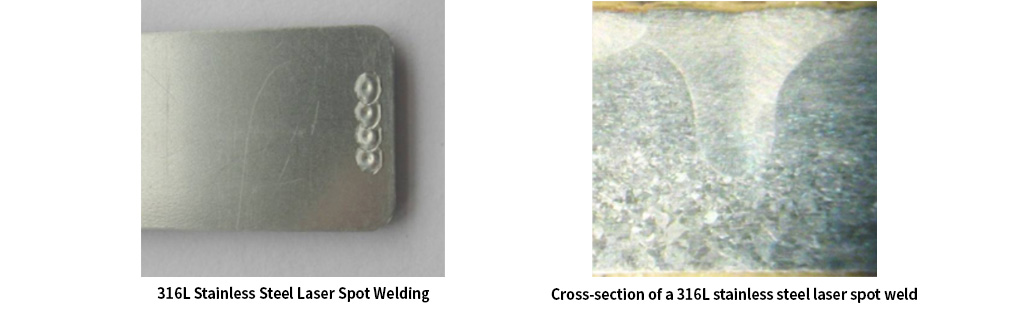

Welding na Karfe da Alloys

·Bakin karfe na iya samun sakamako mai kyau na walda ta amfani da ma'aunin murabba'in igiyar ruwa.

·Lokacin zayyana sifofin walda, yi ƙoƙarin kiyaye wuraren walda daga abubuwan da ba na ƙarfe ba gwargwadon yiwuwa.

·Don saduwa da ƙarfi da buƙatun bayyanar, yana da kyau a tanadi isasshen yankin walda da kauri na workpiece.

·Lokacin waldawa, yana da mahimmanci don tabbatar da tsabtar kayan aikin da bushewar yanayi.

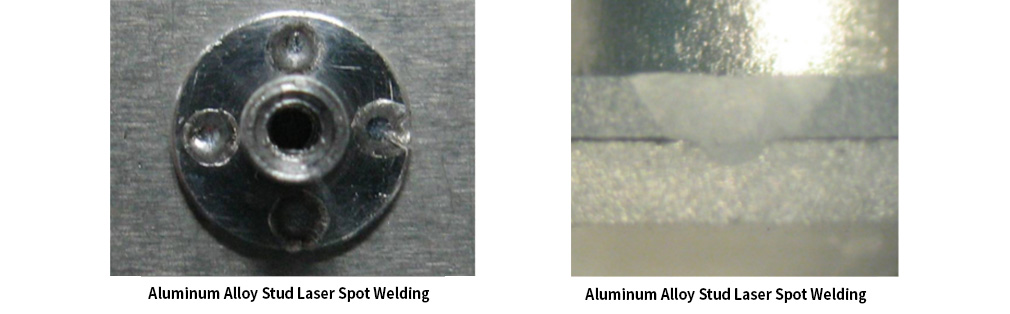

Welding na Aluminum da Alloys ta

·Aluminum gami kayan suna da babban tunani;don haka, ana buƙatar babban ƙarfin Laser kololuwa yayin walda.

·Cracks suna yiwuwa faruwa a lokacin bugun jini tabo waldi, shafi walda ƙarfi.

·Abubuwan da ke tattare da kayan abu yana da sauƙi ga rarrabuwa, yana haifar da splattering.Yana da kyau a zabi kayan albarkatun kasa masu inganci.

·Gabaɗaya, yin amfani da girman girman tabo da tsayin bugun bugun jini na iya samun kyakkyawan sakamako na walda.

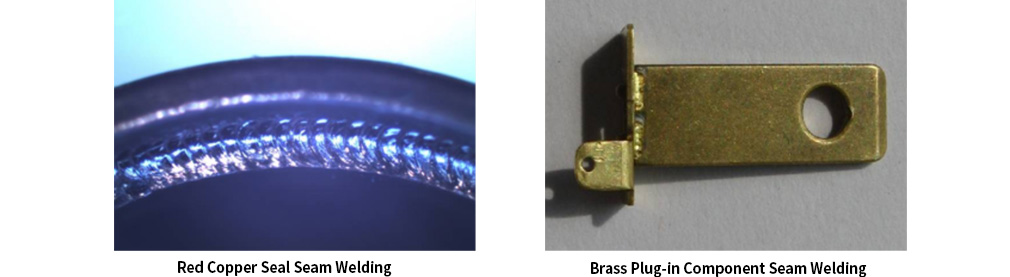

Welding na Copper da Alloys

·Copper kayan suna da mafi girma reflectivity idan aka kwatanta da aluminum gami, bukatar mafi girma ganiya Laser ikon waldi.Ana buƙatar karkatar da kan Laser a wani kusurwa.

·Ga wasu allunan jan ƙarfe, irin su tagulla da tagulla, wahalar walda tana ƙaruwa saboda tasirin abubuwan gami.Ya kamata a biya hankali ga zaɓin sigogin tsarin walda.

Matsakaicin Welding Karfe

·Za a iya samar da ingantaccen bayani.

·Shin akwai babban bambanci a cikin electronegativity tsakanin nau'ikan karafa iri-iri.

·Sauran abubuwan da ke tasiri.

Ko dissimilarari na ƙarfe na iya samar da haɗin gwiwar wadataccen walwala da yawa musamman dogara da kayan jiki, kaddarorin sunadarai, da matakan sunadarai da za a welded.Yawancin lokaci ana la'akari da wannan daga abubuwa masu zuwa:

·Ko za a iya samar da ingantaccen bayani ya dogara ne akan ko ƙananan karafa na iya narkar da juna a cikin ruwa da daskararrun jihohi.Sai kawai lokacin da za su iya narke a cikin juna har abada, za a iya samar da haɗin gwiwa mai ƙarfi da ƙarfi.Gabaɗaya, mahimmin solubility, ko ma mara iyaka, ana iya samuwa ne kawai lokacin da bambancin radius na atomic tsakanin karafa biyu bai wuce kusan 14% zuwa 15%.

·Ko akwai babban bambanci a cikin electronegativity tsakanin nau'ikan karafa iri ɗaya shima yana da mahimmanci.Mafi girman bambancin, ƙaƙƙarfan alaƙar sinadarai, wanda ke haifar da samuwar mahadi maimakon ingantattun mafita.A sakamakon haka, an rage ƙarancin ƙarfi na ƙaƙƙarfan bayani wanda aka kafa, kuma ƙarfin haɗin gwiwa yana da ƙasa.

·Bugu da ƙari, walda na nau'ikan karafa iri-iri yana da matukar tasiri ta kaddarorin kamar wuraren narkewa, ƙididdiga na haɓaka yanayin zafi, abubuwan zafi, ƙayyadaddun zafi, oxidizability, da haskaka abubuwan da abin ya shafa.Babban bambanci a cikin waɗannan kaddarorin jiki, mafi ƙalubalanci shi ne walda, kuma mafi raunin ƙarfin haɗin haɗin gwiwar da ke haifarwa ya kasance.

·Yawanci, waldawar Laser na kayan ƙarfe iri-iri irin su ƙarfe tare da jan karfe, aluminum, da nickel, da jan ƙarfe tare da nickel, suna nuna kyakkyawan walƙiya, wanda ke haifar da ingancin walda mai gamsarwa.

walda Laser yana samun aikace-aikace masu yawa a sassa daban-daban, gami da amma ba'a iyakance ga yankuna masu zuwa ba:

1: Bambancin Welding Karfe

Ana amfani da waldawar Laser sosai a masana'antun masana'antu kamar na kera motoci, sararin samaniya, lantarki, da injiniyan injiniya.Ana amfani dashi don abubuwan waldawa da haɗa tsarin, haɓaka ingantaccen samarwa da ingancin samfur.

2: Na'urorin Lafiya

A cikin kera na'urorin likitanci, ana amfani da walƙiya ta laser don haɗawa da haɗawa da ƙanana, daidaitattun abubuwan haɓaka, tabbatar da samfuran inganci yayin guje wa tasirin zafi mai yawa akan kayan.

3: Lantarki

Saboda madaidaicin madaidaicin shigarsa da ƙarancin zafi, ana amfani da walda ta Laser sosai a cikin kera na'urorin lantarki, gami da walƙiyar allon kewayawa da abubuwan microelectronic.

4: Aerospace

Ana amfani da walda na Laser a fannin sararin samaniya don kera jiragen sama da abubuwan haɗin sararin samaniya, yana ba da damar ƙira mara nauyi da haɗin gwiwa mai ƙarfi.

5: Bangaren Makamashi

A cikin masana'antar makamashi, ana amfani da walda na laser don kera bangarorin hasken rana, kayan aikin makamashin nukiliya, da sauran abubuwan da suka shafi samar da makamashi.

6: Kayan Ado da Agogo

Ganin yadda ya dace da tsari mai kyau da rikitarwa, ana amfani da walda na Laser sau da yawa a cikin kera kayan adon da agogo don haɗawa da gyara abubuwa masu laushi.

7: Masana'antar Motoci

A cikin masana'antar kera motoci, ana amfani da waldi na Laser don haɗa abubuwan haɗin mota, haɓaka haɓakar walda, da haɓaka ingancin samfur.

Overall, da high daidaito, gudun, da kuma versatility na Laser waldi sanya shi yadu zartar a masana'antu da samar filayen.

由用户整理投稿发布,不代表本站观点及立场,仅供交流学习之用,如涉及版权等问题,请随时联系我们(yangmei@bjjcz.com),我们将在第一时间给予处理。

Lokacin aikawa: Janairu-17-2024