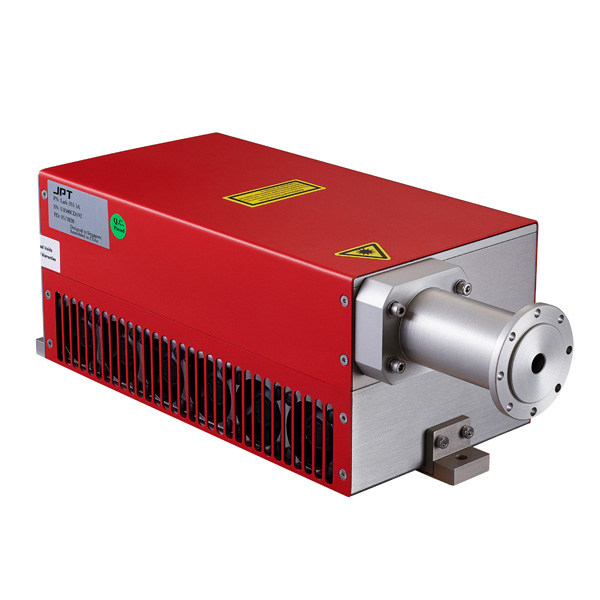

Ultraviolet (UV) Laser 355nm- JPT Lark 3W Air Cooling

JPT UV Laser Lark Series 355nm, 3W, Air Cooling

Lark-355-3A is the latest UV product of the Lark series, which adopts a thermal management method combining conduction heat dissipation and air convection heat dissipation. Compared with Seal-355-3S, it does not require a water chiller.

Comparing with other brands, in terms of optical parameters, the pulse width is narrower (<18ns@40 KHZ), the repetition frequency is higher (40KHZ), the beam quality is better(M2≤1.2), and higher spot roundness (> 90%); In terms of structural design, it is smaller in size, lighter in weight, and more beautiful; In terms of electrical control design, it has stronger anti-electromagnetic interference capability, higher thermal management efficiency, and a more friendly GUI interactive interface.

These characteristics make Lark-355-3A have better structural stability and stronger environmental adaptability, and then achieve features like good beam quality, high power stability, long lifespan, high consistency, easy to install, and maintenance-free...

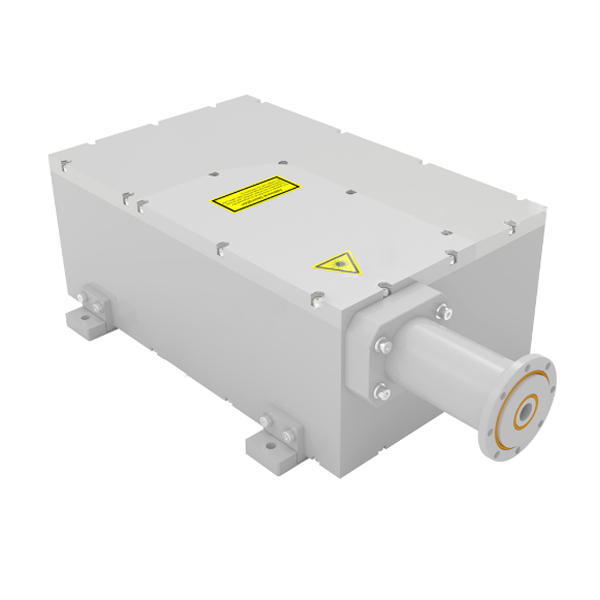

Product Picture

Why Buy From JCZ?

As a strategic partner, we get an exclusive price and service.

JCZ gets the exclusive lowest price as a strategic partner, with thousands of annually ordered laser. Therefore, an competitive price can be offered to customers.

It is always a headache issue for customers if the main parts like a laser, galvo, laser controller are from different suppliers when need support. Buying all the main parts from one reliable supplier seems to be the best solution and obviously, JCZ is the best option.

JCZ is not a trading company, we have more than 70 professional laser, electrical, software engineers, and 30+ experienced worker in the production department. Customized services like customized inspection, pre-wiring, and assembly are available.

FAQs

The reason why ultraviolet light is better than infrared light waves and visible light waves is that ultraviolet lasers directly destroy the chemical bonds connecting the atomic components of the substance. This method, called the "cold" process, does not generate heating to the periphery but directly separates the substance into atoms, without destroying the surrounding environment. The ultraviolet laser has the advantages of short wavelength, easy focusing, energy concentration, and high resolution. It also has high processing precision, narrow linewidth, high quality, small heat effect, good long-term stability, and can process various irregular graphics and irregular patterns. It is mainly used in fine micromachining, especially high-quality drilling, cutting and grooving treatments. Uv laser has been successfully applied in metals, semiconductors, ceramics, glass, and various polymer materials.

A blue right light is integrated for preview and a 6X/10X beam expander is optional. Please share your application, and our engineer will suggest which expander will be suitable.

Specifications

| Parameter Unit | Parameter |

| Product Model | Lark-355-3A |

| Wavelength | 355 nm |

| Average Power | >3 w@40 kHz |

| Pulse Duration | <18ns@40kHz |

| Pulse Repetition Rate Range | 20 kHz-200 kHz |

| Spatial Mode | TEM00 |

| (M²)Beam Quality | M²≤1.2 |

| Beam Circularity | >90% |

| Beam Full Divergence Angle | <2 mrad |

| (1/e²)Beam Diameter | Non-expanding:0.7土0.1 mm |

| Polarization Ratio | >100:1 |

| Polarization Orientation | Horizontal |

| Average Power Stability | RMS≤3%@24 hrs |

| Pulse to Pulse Energy Stability | RMS≤3%@40 kHz |

| Operating Temp | 0℃~40℃ |

| Storage Temp | -15℃~50℃ |

| Cooling Method | Air-cooling |

| Supply Voltage | DC12V |

| Average Power Consumption | 180 w |

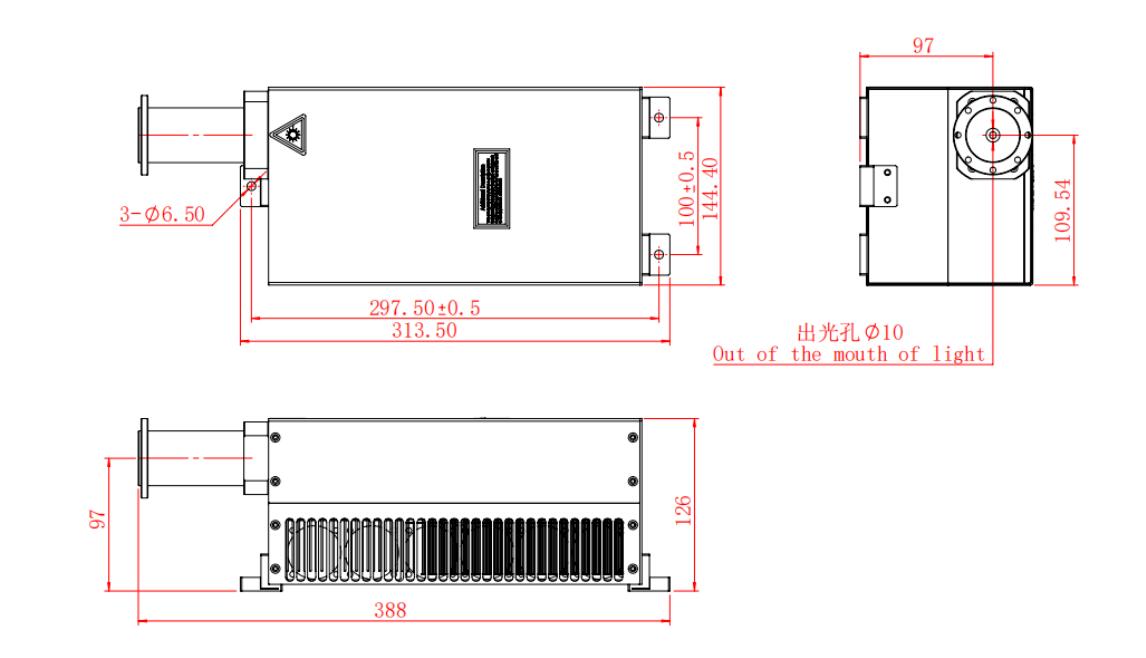

| Three-Dimensions | 313×144x126 mm(WxDxH) |

| Weight | 6.8 kg |