Solution for Laser Surface Etching of Battery Electrode Sheets

With the increasing requirements for industrial manufacturing automation and intelligence in China, laser processing control technology has been continuously innovating and upgrading, laser processing is excellent processing characteristics have been widely applied across various fields.

In the production and manufacturing process of batteries, laser processing technology is being used in more and more stages, Laser has become a highly effective technology for reducing costs and increasing efficiency in battery production.

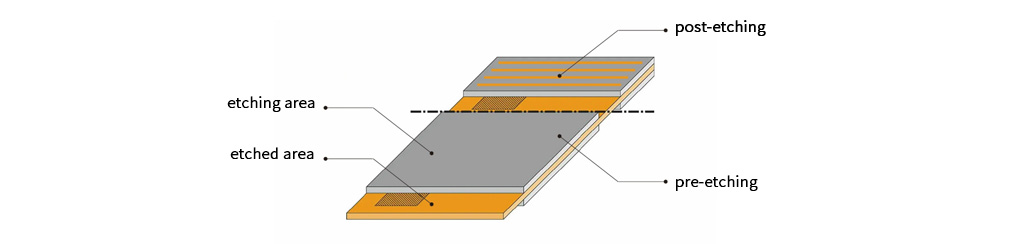

In order to improve battery performance, In the production and manufacturing process of battery electrode sheets, Production process of laser etching using laser marking technology on the coating layer of battery electrode sheets. This process uniformly etches the coating on both sides of the electrode sheets, forming evenly deep etched lines on the coating layer of the electrode sheet.

Laser processing is a non-contact processing method that does not cause mechanical deformation to the battery electrode sheets, Its flexible laser process parameter adjustments can meet different etching depth and length requirements. Laser processing is highly efficient and can match the coil-to-coil mechanism's material speed,enabling in-flight etching processing.

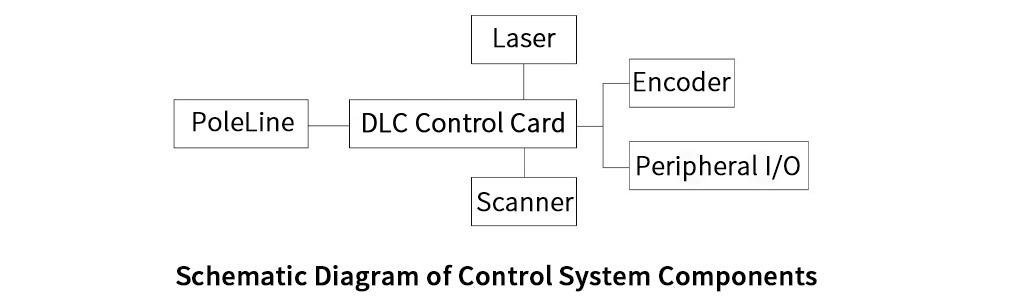

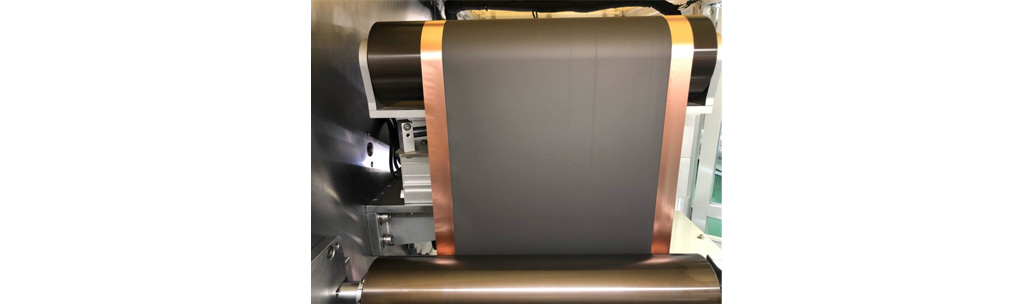

JCZ Technology has deep expertise in laser mirror control and has mastered several patented technologies and rich laser processing application experience in the field of battery laser processing. Based on this, JCZ Technology has launched the Electrode Line Processing System specifically for the application of laser surface etching of battery electrode sheets.

Key Features

Multi-head in-flight synchronous processing, with control of up to 32 galvo processes.

Adaptive walking speed processing to ensure good line spacing and splicing accuracy in variable speed mode.

Support for various electrode sheet coating structures including MMT/ASC/USC/SFC.

Support for coating area position locking function.

Support slot avoidance, support various etching rules.

Core Technologies

Multi-head in-flight control technology

Independently developed flying position dynamic compensation algorithm and multi-mirror control technology, supporting compensation splicing processing for multi-mirror variable speed motion positions.

High-precision mirror calibration technology

Featuring multi-point calibration function, allowing users to customize calibration points for mirror distortion correction, with a high full-face mirror calibration accuracy of up to ±10um (250*250 mm area).

Laser control technology

Comprehensive laser control interface, supporting common laser control, laser status and power monitoring, and power feedback compensation.

Deflection compensation technology

Based on deflection sensor-detected electrode sheet position information, controlling mirror real-time compensation of electrode sheet Y-direction position deviation, ensuring precise positioning of etched lines.

以上内容主要来自于金橙子科技,部分素材来源于网络

Post time: Dec-29-2023